You see the final, shimmering hologram sticker, but how did it get there? The manufacturing process seems like a mysterious "black box," and you're worried about trusting a supplier when you don't understand how they ensure quality, security, and on-time delivery.

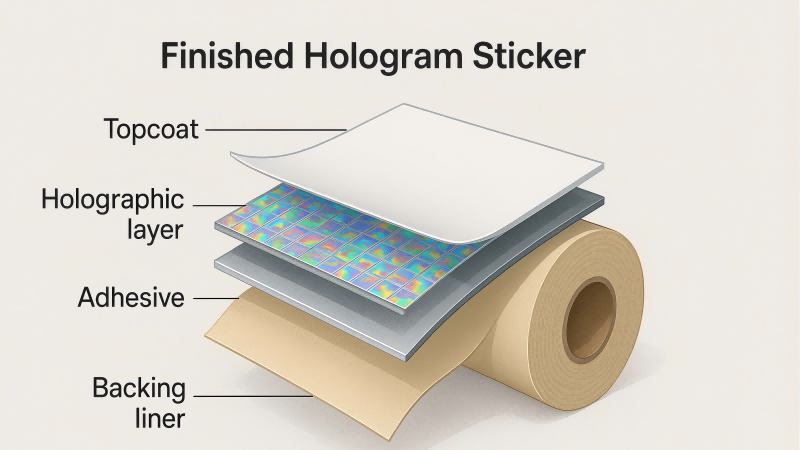

First, a laser creates a microscopic master plate, which embosses the holographic pattern onto film. Next, adhesive and a backing liner are applied to this film. The roll is then printed with any serial numbers and finally precision die-cut into individual, finished stickers, ready for application.

Over my 15+ years in this industry, I've learned that the true value of a security sticker manufacturer isn't about having one advanced machine. It's about having what I call "Process Sovereignty." Many suppliers are little more than "assembly plants"—they outsource mastering to one factory, embossing to another, and adhesive coating to a third. A truly professional manufacturer, however, masters the entire chain under one roof. This end-to-end control is the fundamental guarantee of quality, security, and reliable delivery. This tour will show you exactly what that means at each critical stage.

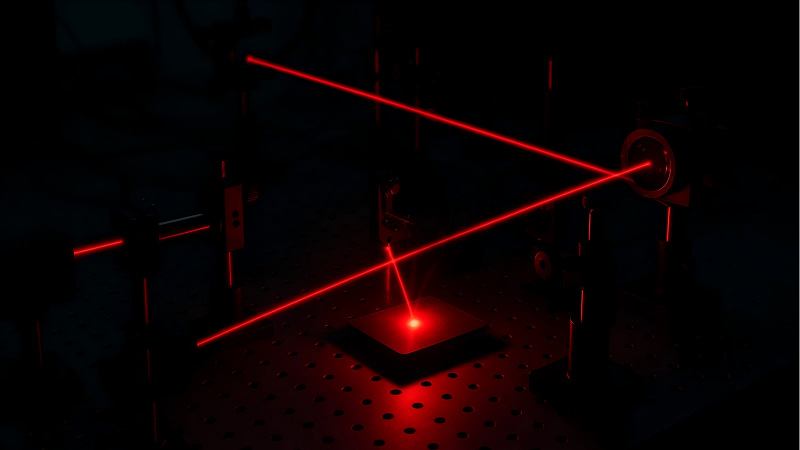

How Is the Original Security Design Transformed into a Metal Master Plate?

You've approved a digital design file. You're now wondering how that computer file becomes the physical origin point for millions of stickers.

The digital design is transformed into a metal master plate through a process called holographic mastering and electroforming. First, a laser-based system etches the design as a microscopic relief pattern onto a photosensitive plate. This plate is then used to grow a solid nickel "master shim."

This is the most sensitive step, and it’s where Process Sovereignty is paramount. This master plate is the "DNA" of your hologram's security.

Why In-House Mastering Matters

In an "assembly plant" model, your unique master plate would be created at a third-party facility. This means the very blueprint of your security feature physically leaves the control of your supplier, creating a massive security risk. The master could be copied, "lost," or used to run an unauthorized third shift for counterfeiters. By keeping mastering in-house, under our own roof, we ensure your security DNA never leaves our secure facility. It moves from our lab directly to our production floor, with a complete chain of custody. This isn't just a quality control measure; it's a fundamental security protocol that outsourced models simply cannot provide.

What Happens During High-Pressure Embossing to Create the Holographic Film?

You have a single, palm-sized metal master. How does this one small plate create kilometers of holographic film with perfect consistency?

The metal master is used to create production copies, which are welded onto a large embossing roller. This roller is heated and pressed against a roll of thin PET film with immense pressure, transferring the microscopic pattern from the metal onto the film at high speed.

This is where industrial-scale consistency is forged. The visual quality of your hologram depends entirely on the precision of this step.

The Advantage of Integrated Embossing

When embossing is outsourced, there's a disconnect. The embossing factory may not know the specific nuances of the master they received. They might use the wrong temperature or pressure, resulting in a dull or inconsistent holographic effect. If a quality issue arises, the blame game begins. The assembly plant blames the embosser, who blames the master-maker. At a fully integrated factory, our embossing technicians work directly with the mastering team. They are calibrated to one another. If an issue is detected, our teams can walk 30 meters to the other department and solve the problem in minutes, not days. This tight feedback loop guarantees that the millionth impression is as sharp and bright as the first.

How Is Adhesive Applied to Turn That Film into a Functional Sticker Roll?

The embossed film is beautiful but useless—it's just a shiny plastic sheet. You need it to stick reliably to your specific product, from cardboard boxes to painted metal.

The embossed film is run through a specialized coating machine. Here, multiple crucial layers are applied, including a reflective metallic layer, the correct pressure-sensitive adhesive for your product's surface, and a protective release liner on the back.

As someone who started in quality control, I can tell you this step is where many projects fail. A brilliant hologram with the wrong adhesive is a defective product.

The Power of In-House Adhesive Expertise

An "assembly plant" supplier typically buys pre-coated materials from a giant chemical company. They might have a few standard adhesive options that are "good enough." At an integrated facility with Process Sovereignty, we have our own coating lines and deep expertise in adhesive chemistry. We don't just offer A, B, or C; we select and fine-tune the exact adhesive formulation your project needs. Is your product a textured plastic that requires a high-tack rubber-based adhesive? Or a high-gloss varnish that needs a specific acrylic adhesive to avoid residue? We control this choice, ensuring the sticker's functionality matches its security.

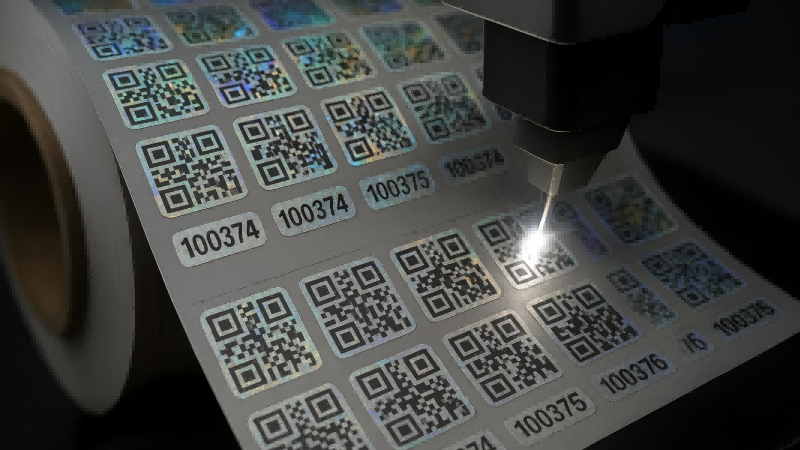

How Are Serial Numbers and Other Features Printed onto the Sticker Material?

Your hologram requires a unique serial number or QR code for track-and-trace. You're concerned about how these variable data are printed accurately and securely.

After the adhesive is applied, the roll of material is moved to a printing station. Here, high-speed inkjet or laser marking systems add the variable data, like sequential numbers, barcodes, or QR codes, directly onto the surface of each holographic label.

This process adds another layer of security and functionality, but it also introduces another risk if not handled in-house.

The Security of Integrated Printing

Outsourcing this step means sending your holographic material—and the sensitive sequence of serial numbers—to yet another factory. This creates an opportunity for over-runs or for the number sequence to be compromised. When the printing process is part of our integrated workflow, we maintain full control. The numbering is managed by our secure IT system, and the physical printing happens right on our production floor. Our QC team can immediately verify the print quality and number accuracy. This eliminates the possibility of data leakage and ensures every single number is accounted for, a guarantee that is simply not possible in a fragmented supply chain.

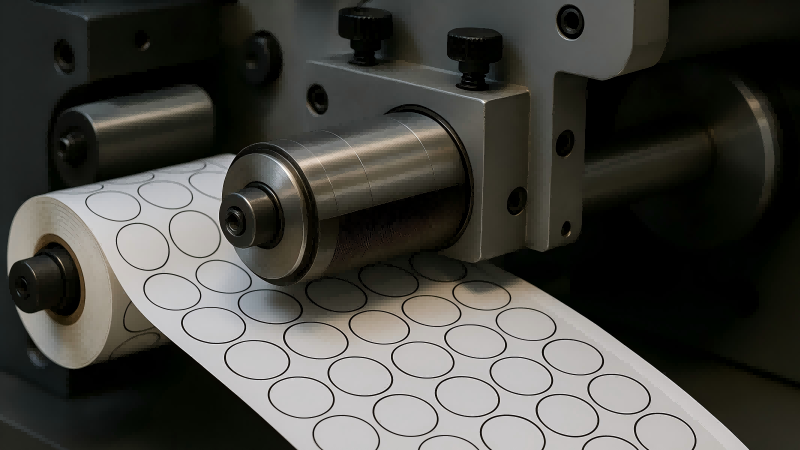

What's the Final Process to Cut the Roll into Individual, Finished Stickers?

You have a giant, finished roll containing thousands of impressions. The final step is to turn this into usable labels that work perfectly, whether applied by hand or by a high-speed machine.

The finished roll is loaded onto a precision die-cutting machine. This machine uses a sharp, custom-made "die" to cut the top sticker material into the final shape without cutting the backing paper below, creating a finished roll of easy-to-peel stickers.

This sounds simple, but precision here is everything. This is the final test of a manufacturer's commitment to quality.

Why Integrated Die-Cutting Ensures Reliability

If your labels are meant for an automatic applicator, the spacing between them must be consistent to within a fraction of a millimeter. An outsourced die-cutter won't understand the specific tolerances of your machine. This can lead to catastrophic jams and downtime on your production line. Because we control the die-cutting process, we can fine-tune it to your exact specifications. We can adjust the blade depth, the spacing, and the roll tension. Before we ship, our QA team performs peel tests and measures tolerances, confirming that the final roll will perform flawlessly for you. This is the final step where Process Sovereignty delivers tangible, real-world value.

Conclusion

A security hologram sticker is a product of a fully controlled, end-to-end manufacturing process. "Process Sovereignty" is what separates a true manufacturing partner from a simple assembler, ensuring unmatched security, quality, and reliability.

Partner with a True Manufacturer

Don't risk your brand's security with a fragmented supply chain. At ProtegoSeal, we control the entire manufacturing process under one roof. Contact us to experience the confidence that comes from genuine Process Sovereignty.