You applied a VOID label to your product, but it created a new problem. It either left a sticky, hard-to-clean mess on your reusable case or left no trace at all on the box, making your tampering claim impossible to prove.

Choosing the right VOID label is critical. Full residue labels leave a permanent message on the surface, making them ideal for disposable packaging. In contrast, non-residue labels show tampering only on the label itself, protecting the surface of reusable or high-value assets from damage.

Clients often ask me the wrong question. They ask, "How can I get a lower price?" But after years of seeing the consequences of that question, I've learned to reframe it. The right question is, "What is the total cost of this label?" A cheap label that fails to stick or damages your product can lead to a $10,000 lost dispute. Its real cost is enormous. A slightly more expensive label that is perfectly matched to your needs and prevents that one dispute has a real cost of just its purchase price. This is the difference between buying a cheap sticker and investing in a low-cost, high-value certainty.

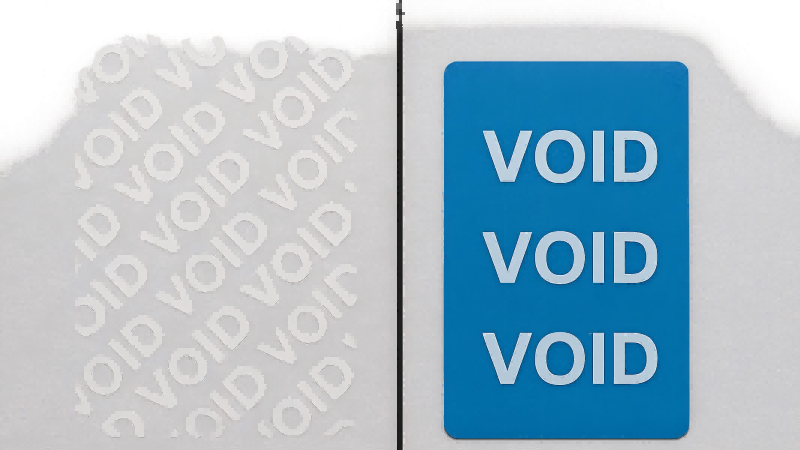

What is a Full Residue VOID Label and When to Use It?

A full residue VOID label is a security sticker that leaves a permanent, sticky 'VOID' message on the surface it was applied to. You should use it in specific situations where proving a package was opened is the top priority, and the package itself is disposable.

This is the label you choose when there can be no ambiguity. Its entire purpose is to provide undeniable physical evidence on the surface itself. The technology is straightforward: the adhesive bond to the surface is stronger than the internal layers of the label. When peeled, it deliberately splits, leaving a patterned layer of adhesive residue behind. To directly answer when you should use it, let's look at the exact scenarios where this feature is necessary.

| Situation (When to Use It) | Reason |

|---|---|

| Sealing disposable shipping cartons | To provide clear proof of in-transit tampering for carriers and recipients. |

| Securing legal evidence bags | To maintain the chain of custod. The residue proves the bag has been opened. |

| Protecting single-use containers | To secure items like medical test kits or cash-in-transit boxes where the container will be destroyed after use. |

| Closing software or license packaging | To show that a product box or license envelope has been opened, thus voiding return policies. |

In every one of these cases, you are intentionally sacrificing the surface to gain irrefutable proof. For a disposable item, this is a perfect trade-off.

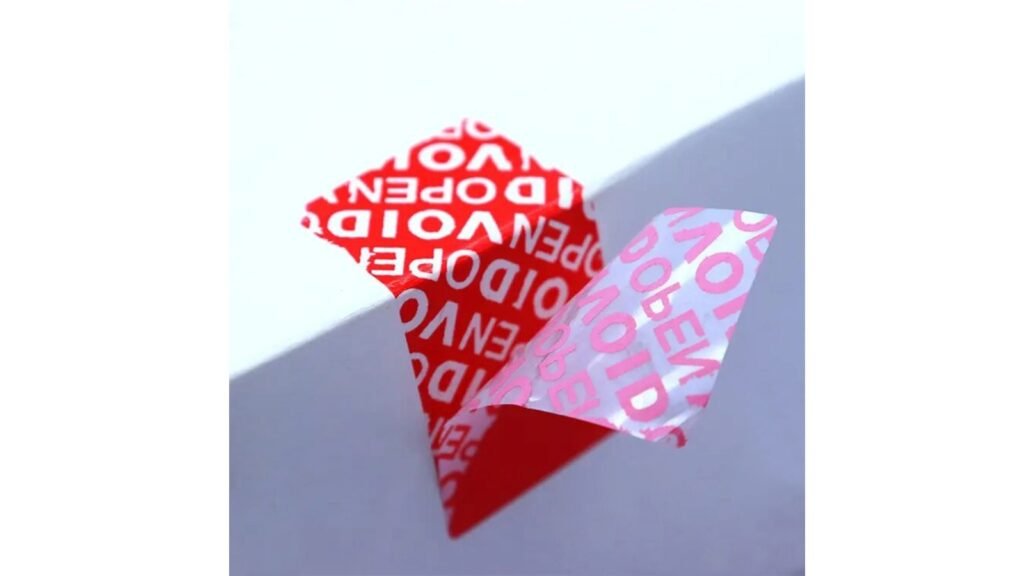

What is a Non-Residue VOID Label and Its Ideal Applications?

A non-residue VOID label is a security sticker that reveals a 'VOID' message only on the label itself when tampered with, leaving the asset's surface perfectly clean. Its ideal applications are on high-value or reusable assets like server cabinets, aircraft panels, or rental equipment where surface damage must be avoided.

Here, the label is engineered differently. The top layers of the label are designed to separate, revealing a hidden message within the sticker without transferring any adhesive pattern to the surface. The main reason for choosing this label is to protect the asset itself. Because it leaves no residue, the asset can be immediately returned to service after the seal is removed, saving significant labor costs for cleaning and preventing surface damage.

| Ideal Applications | Why It's the Right Choice |

|---|---|

| Aircraft Doors & Panels | Secures hatches and compartments between checks without damaging the aircraft skin. |

| Server/IT Cabinets | Provides access control evidence for data centers without leaving residue on expensive equipment. |

| Rental Equipment | Seals items to show they haven't been tampered with, without creating cleanup for the next renter. |

| Retail Electronics | Seals product boxes in a way that doesn't damage the cosmetic packaging for display. |

Choosing a non-residue label is a strategic decision to avoid future costs linked to asset damage or cleanup.

Full Residue vs. Non-Residue: A Head-to-Head Comparison table

The core difference is where the evidence appears: full residue leaves a sticky message on the surface, best for disposable items, while non-residue shows tampering only on the label, protecting reusable assets.

This table provides a direct, head-to-head comparison to make the distinction clear.

| Feature | Full Residue Label | Non-Residue Label |

|---|---|---|

| Evidence Location | On the surface AND the label | On the label ONLY |

| Surface Impact | Leaves a permanent, sticky residue | Leaves the surface perfectly clean |

| Ideal Use Case | Disposable, one-time-use packaging | Reusable, high-value, or cosmetic surfaces |

| Cleanup Required | Yes, often requires solvents and labor | No cleanup required |

| Hidden Cost | High cleanup cost if used on the wrong surface. | High dispute cost if used where surface evidence is required. |

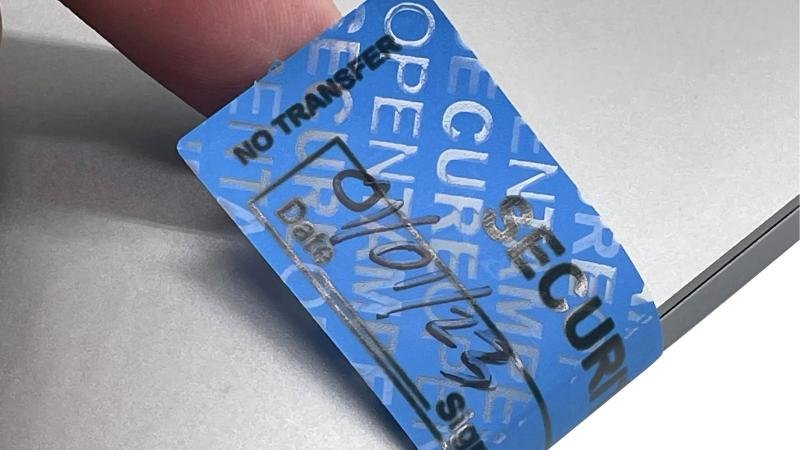

The Critical Factor: Matching the Label Type to Your Product Surface

The most critical factor for success is matching the label's adhesive to your product's surface. If the adhesive doesn't bond correctly, especially on slick, low-energy plastics, the VOID security feature will fail completely, and all your investment will be wasted.

This is a lesson I learned early in my quality control career. A label is only as good as its adhesion. Different materials have different surface properties that affect how well an adhesive can "wet out" and form a strong bond.

Understanding Surface Energy

The main principle here is surface energy.

- High Surface Energy (HSE): Materials like metal, glass, and ABS plastic are easy to stick to. Most standard adhesives work well.

- Low Surface Energy (LSE): Materials like polypropylene (PP) and polyethylene (PE)—common in plastic totes—are very difficult to stick to. Using a standard adhesive on an LSE surface is a recipe for failure.

The Immutable Rule: Test, Test, Test

Before placing a bulk order, you must test the specific label on your actual product surface. A good supplier should provide samples and understand the technical requirements. Ignoring this step is gambling with your asset security.

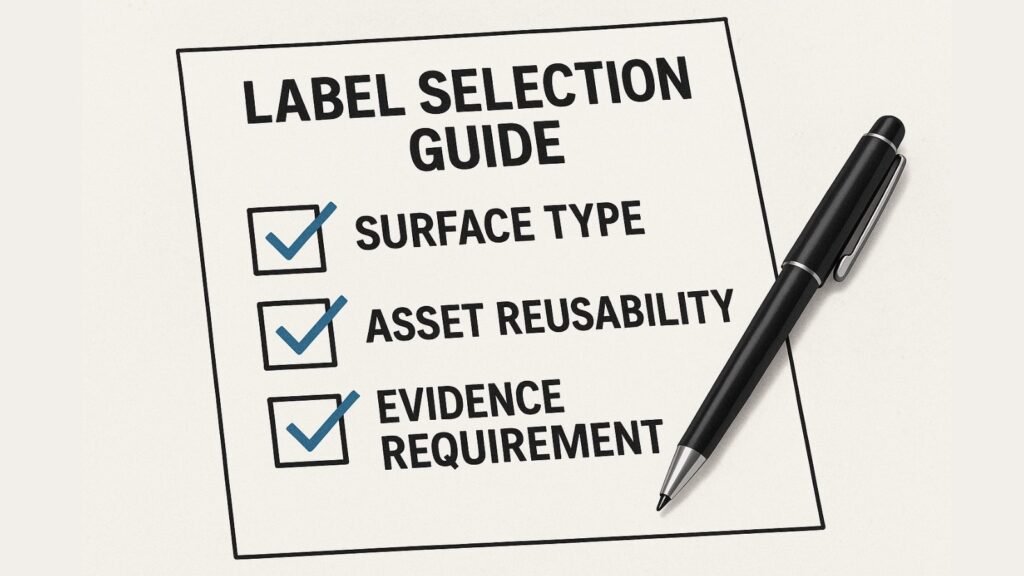

Final Verdict: A Decision-Making Guide for Buyers

This guide provides a final verdict for buyers: use Non-Residue labels for any reusable or high-value surface, and use Full Residue labels for any disposable package where permanent evidence is critical. Following this guide ensures you make the right, most cost-effective choice.

Let's remove the uncertainty. This simple process transforms the purchase from a guess into a calculated business decision that lowers your risk and your total cost of ownership.

Your Decision-Making Checklist

Is the asset reusable, for display, or high-value?

- Yes: Your choice is Non-Residue. You must protect the surface and avoid cleanup costs.

- No: It's disposable. Proceed to the next question.

Is leaving permanent evidence on the surface mandatory for your process?

- Yes: Your choice is Full Residue. Your chain of custody depends on this evidence.

- No: A non-residue label is acceptable if evidence on the label itself is sufficient.

Have you tested the label's adhesive on your specific surface material?

- Yes, and it bonds perfectly: You can proceed with your order, confident in your choice.

- No: Stop. Do not order. Request samples and test first to avoid a complete failure of your security program.

Conclusion

Choosing between full residue and non-residue VOID labels is a strategic decision, not a simple purchase. By focusing on the total cost—including cleanup, disputes, and surface damage—you can select the right tool that provides security and certainty.

Choose Certainty, Not Just a Sticker, with ProtegoSeal

Don't let the wrong label become a hidden cost in your business. Invest in a solution that matches your exact needs and lowers your total risk. At ProtegoSeal, we provide expert guidance to help you choose the right VOID label technology for any application. Contact us to get samples and ensure you're making the most cost-effective decision.