You've found a China factory with an incredibly low price on meter seals. But now the doubt creeps in. What if the quality is terrible? What if a batch arrives with duplicate numbers? A single bad shipment could cause massive financial losses and damage your company's reputation.

Sourcing meter seals isn't about finding the lowest price; it's a strategic investment in a long-term safety commitment. Success depends on your ability to verify a factory's quality, customization capabilities, realistic lead times, certifications, and communication before you place an order.

In my 15 years in this business, I've seen many international buyers focus only on the price per unit. This is a huge mistake. When you are buying for critical infrastructure like power or water utilities, you aren't just buying a piece of plastic. You are buying a long-term "safety commitment" and a reliable "supply chain partner." The success of your entire project won't be determined by the half-cent you saved, but by whether your chosen supplier can deliver on their promises of quality, customization, and delivery time when it matters most. You aren't shopping. You are making a strategic risk investment. Here’s how to make a smart one.

How Do You Validate Quality from Thousands of Miles Away?

The photos and spec sheets from the factory look perfect. But you're worried that the seals that actually arrive will be brittle, weak, or fail in the field, leading to costly recalls and security breaches.

You must move beyond trust to verification. Ask for specific material data, inquire about their mold maintenance schedule, and, most importantly, get physical samples to conduct your own stress tests.

Validating quality from afar is all about asking the right questions. The answers will tell you if you're dealing with a professional factory or a simple workshop.

1. Ask About Raw Materials

Don't just ask if it's "plastic." Ask for specifics.

- For the Body: Is it 100% virgin Polycarbonate (PC)? PC is transparent, rigid, and performs well in a wide range of temperatures. Ask for a data sheet. Some factories cut costs by using cheaper plastics or recycled material, which can become brittle in the cold.

- For the Locking Insert: Is it colored Polypropylene (PP) or ABS? How do they ensure color consistency across batches?

2. Inquire About Molds

A quality seal comes from a quality mold. Ask them: "What is your maintenance schedule for your injection molds?" A good factory overhauls its molds regularly. A bad one runs them until they break. This is why you sometimes see seals with "flash" (thin extra plastic bits) or weak points—the mold is worn out.

3. Test the Samples

When you get samples, don't just look at them. Try to destroy them.

- Pull Test: Try to pull the wire out after sealing.

- Twist Test: Twist the body. Does it crack easily?

- Temperature Test: Put one in your freezer overnight and then test it. Does it shatter?

This simple, hands-on testing is your best insurance against a large-scale quality failure.

Is Their Customization More Than Just a Logo?

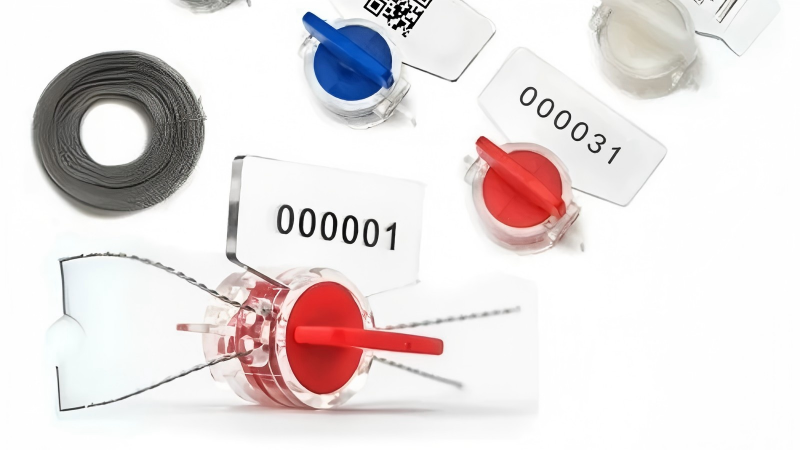

You need a unique, sequential serial number for every single seal. You're afraid a factory might accidentally produce a batch with duplicate numbers, which would completely destroy your audit trail and create a security nightmare.

True customization is about data integrity, not just aesthetics. You need to verify their laser engraving technology for clarity and permanence, their barcoding capabilities for automation, and get an ironclad guarantee on the uniqueness of their serial number sequences.

For a meter seal, the number and barcode are its identity. This is a non-negotiable part of the "safety commitment."

Laser Engraving vs. Hot Stamping

Ask them what marking technology they use. Laser engraving is the industry standard. It's clean, permanent, and allows for very precise barcodes. Hot stamping can be cheaper, but the numbers can sometimes be rubbed off or tampered with. For a high-security application, insist on laser.

Barcode Integration

Can they print a standard barcode (Code 128) or a 2D barcode (Data Matrix, QR)? A barcode allows your technicians to scan the seal with a mobile device, eliminating human error during data entry and speeding up audits. This is a key feature for any modern utility company.

The Serial Number Guarantee

This is the most critical question you can ask: "How do you guarantee that the number sequence you produce for me will never be repeated for any other customer, ever?" A professional factory will have a robust ERP system that manages and retires number sequences. They should be able to explain this system to you. If they can't give you a confident answer, walk away. The risk of duplicate numbers is too great.

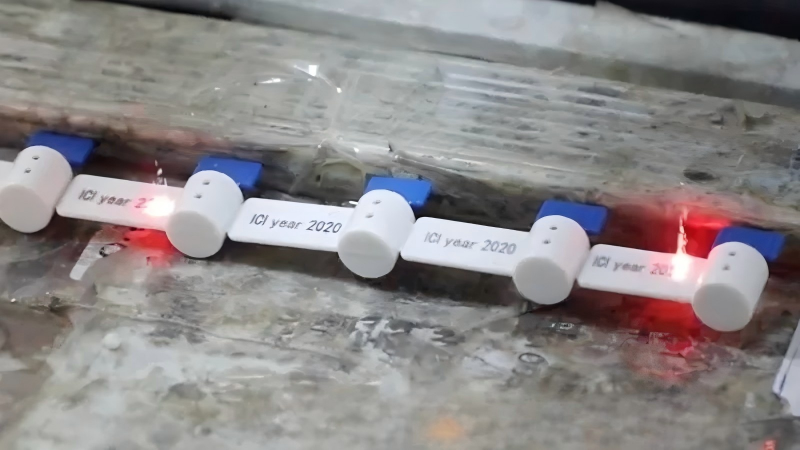

How Do You Deconstruct a Factory's Lead Time Promise?

A factory promises you a 30-day lead time. You place a large order, but 45 days later, it still hasn't shipped. Now your own project timelines are delayed, and you risk angering your customers or stakeholders.

A lead time promise is meaningless without a clear understanding of the factory's actual production capacity. Ask for their daily output, the number of production lines for your specific product, and their current workload.

A reliable supply chain partner gives you realistic dates. Here’s how to dig deeper than the salesperson's promise:

- "How many meter seals can you produce per day?" This single question tells you a lot. A small workshop might produce 5,000 pieces a day. A large, established factory might produce over 200,000.

- "How many production lines do you have dedicated to this type of seal?" More lines mean more flexibility. If one line goes down for maintenance, they can still continue your production on another.

- "Are you currently in a peak production season?" Experienced buyers know that production slows down significantly around major holidays like Chinese New Year. Ask them how they manage orders during these times.

A good supplier will give you transparent answers. They will tell you their capacity and work with you to create a delivery schedule that is realistic. A bad supplier will just tell you what you want to hear to get the deposit.

How Do You Know Their Paperwork Is Real?

The supplier sends you a slick PDF with an ISO 9001 certificate. It looks official, but how do you know it's a legitimate, current certification and not just a document that was edited in Photoshop?

The proof is in the paperwork, but only if you can independently verify it. Ask for their certification numbers and use official online databases to check their validity. A trustworthy partner will be transparent with this information.

Essential certifications are a baseline indicator of a factory's commitment to quality and process management. Don't just accept the document; check the source.

- ISO 9001: This is the most fundamental certification for quality management systems. It doesn't guarantee a perfect product, but it proves the factory has defined, documented, and audited processes for production and quality control. Ask for the certificate and check the issuing body's website to confirm it's valid.

- Product-Specific Certifications: For some applications, you may need seals that comply with specific standards. If they claim compliance with something like ISO 17712 (for high-security seals, not typically meter seals), they must provide a certificate from an accredited lab.

A supplier who is hesitant to let you verify their certifications is a major red flag. This is a critical part of your due diligence in your strategic investment.

Are You Evaluating Their Communication and Support?

You've approved the quality and the price. But every time you email your sales contact, it takes three days to get a vague, one-sentence reply. What happens if there's a serious problem with your shipment?

You are not buying a product; you are starting a relationship. Evaluate the sales representative's responsiveness, English proficiency, and technical knowledge. This person is your lifeline to the factory, and their support is as important as the seal itself.

After a problem occurs is the wrong time to discover your supplier has terrible support. Judge them from the very first interaction.

- Responsiveness: How quickly do they reply to your inquiries? Are their answers clear and complete, or do you have to ask the same question three times?

- Technical Knowledge: Does your contact understand the product? Can they intelligently discuss material specifications and customization options, or do they just keep repeating the price? You need a partner who can solve problems, not just take orders.

- Problem Resolution: Ask them a hypothetical question: "If a shipment arrives and 5% of the seals are defective, what is your process for fixing this?" A good supplier will have a clear policy for replacements or credits. A bad supplier will become defensive or disappear.

I've learned that the quality of a factory's communication is often a direct reflection of the quality of its management and its products.

Conclusion

Sourcing meter seals from China is a strategic investment in your supply chain and security infrastructure. By thoroughly vetting a supplier's quality, customization capacity, lead times, certifications, and communication, you can build a reliable partnership that mitigates risk and ensures long-term success.

Make Your Strategic Investment with ProtegoSeal

Building a reliable supply chain requires a partner who understands the stakes. At ProtegoSeal, we provide transparent communication, verified quality, and a deep commitment to delivering on our promises. We are not just a supplier; we are your strategic partner in security. Contact us to discuss how we can de-risk your next procurement project.