A nurse is fumbling for scissors to cut a heavy-duty seal on a crash cart during a code blue. Elsewhere, an audit reveals a missing narcotic, but the simple, unnumbered seal on the drug cabinet offers no chain of custody.

In a clinical setting, the right tamper-evident seal is a critical process tool. The choice depends on the specific application: crash carts need instant, tool-free access, while drug cabinets require serialized seals for strict accountability.

In my experience advising hospitals and clinics, I've seen firsthand how the wrong seal choice can have dire consequences. A seal in a clinical environment is never just an isolated "lock." It is a process management tool, and its design must serve the highest priority of its specific scenario. Placing a seal meant for a crash cart on a drug cabinet is a serious compliance failure. The right choice always involves finding the perfect balance between three critical variables:

- Speed of Access: How quickly can the contents be reached in an emergency?

- Level of Accountability: How strong is the audit trail for compliance and controlled substances?

- Ease of Audit: How efficiently can staff check and replenish supplies during daily routines?

The way you balance these three points directly determines the safety and efficiency of your clinical workflows. Let's explore how to find that balance.

What Does "Tamper-Evident" Really Mean in a Clinical Setting?

Your staff thinks "tamper-evident" means a seal that's hard to break. This misunderstanding leads them to use overly strong seals in the wrong places, creating dangerous delays and frustration.

In a clinical context, a tamper-evident seal is not about physical strength. It's about providing a clear, immediate, and 100% binary answer to a simple question: "Has this been opened since it was last restocked and checked?"

This is the unifying principle for all seals used in healthcare. Unlike securing a shipping container, the goal isn't to stop a thief with bolt cutters. The goal is to create an undeniable visual signal that an item has been accessed. This signal is a critical piece of communication that triggers a specific action: "This cart/kit needs to be restocked and resealed." A good clinical seal provides this information instantly and without ambiguity. When intact, it guarantees that the contents are sterile, complete, and ready for use as per the last inspection. A broken seal, conversely, guarantees that the contents are no longer verified. It is this clear, visual communication that underpins the entire system of patient safety and inventory control in a hospital.

For Crash Carts: Why Is a Breakaway Seal a Lifesaving Feature?

During a cardiac arrest, a nurse grabs the crash cart, but the seal is a tough pull-tight model that won't break by hand. The 10 seconds spent searching for scissors are 10 seconds lost from a patient's life.

A breakaway seal is designed to be broken with a single, quick twist of the hands—no tools required. In an emergency, this prioritizes the variable of Speed of Access above all else, ensuring zero delay when every second counts.

When a "code blue" is called, there is no time for anything but immediate action. A crash cart is the perfect example of a scenario where Speed of Access is the non-negotiable priority. A standard pull-tight seal, while secure, is a catastrophic failure in this context because it requires a cutting tool. A breakaway seal is the only acceptable choice here.

The Critical Design Difference

- Breakaway Seal: Features a scored or intentionally weak point in the plastic. A firm twist and pull is enough to snap it cleanly.

- Pull-Tight Seal: Designed like a zip-tie, it gets tighter when pulled and requires scissors or a blade to remove.

I have seen hospitals standardize on breakaway seals for all emergency response equipment. They understand that the seal's job isn't to be strong; its job is to break instantly when needed, while still providing clear tamper evidence for routine checks. In this case, sacrificing a small amount of security for maximum accessibility isn't just a good idea—it's a critical component of emergency medical response protocol.

For Drug Cabinets: Why Is a Serialized Seal Critical?

An audit of the narcotics cabinet reveals a discrepancy. The log shows the cabinet was sealed, but the simple, unnumbered seal that was used offers no proof of who accessed it or when, leaving the hospital liable.

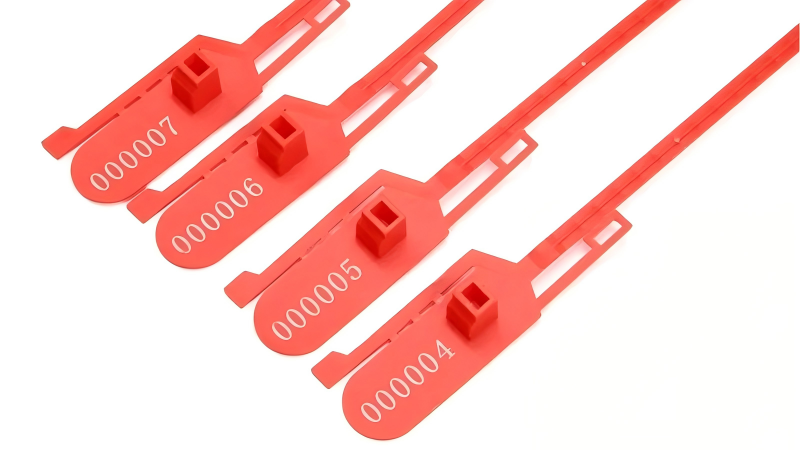

A serialized, high-security seal provides a unique identification number that is logged upon application and removal. This prioritizes Level of Accountability, creating a legally-defensible chain of custody for controlled substances.

When securing narcotics and other high-value controlled substances, the balance shifts dramatically. Here, accountability to regulatory bodies like the DEA is the top priority. A simple breakaway seal is completely inappropriate. You need a seal that provides a unique identity.

This is where pull-tight seals with permanent serial numbers come in.

- Unique Identification: Each seal has a unique number that cannot be replicated.

- Clear Audit Trail: When a nurse seals the cabinet, they record the date, time, their initials, and the seal number in a log.

- Verified Access: The next person to access the cabinet must verify that the seal number in the log matches the one on the cabinet before breaking it. They then repeat the process when re-sealing.

Any discrepancy in the number sequence provides immediate proof of an unauthorized entry. This creates an unbroken chain of evidence that is essential for both loss prevention and regulatory compliance.

For Medical Kits: How Can Color-Coding Speed Up Audits?

A nurse starts their shift and needs to quickly verify that dozens of different medical kits (e.g., intubation, IV start, suture kits) are stocked and ready. Checking each one individually is slow and inefficient.

Using color-coded, pull-tight seals allows staff to verify the status of entire groups of kits at a single glance. This strategy prioritizes Ease of Audit, dramatically improving operational efficiency.

For routine medical kits, the highest priority is often making the daily audit process as fast and error-proof as possible. This is where a visual management system using color is incredibly effective. Instead of reading dozens of tiny serial numbers, staff can assess the status of an entire room in seconds.

Implementing a Color-Code System:

- Assign Colors by Month: All kits restocked in July get a green seal. All kits restocked in August get a yellow seal. A quick glance at the supply closet shows which kits are oldest and may need to be checked for expired items first.

- Assign Colors by Kit Type: All IV start kits get a blue seal. All suture kits get a red seal. This helps staff quickly identify the correct kit from a distance.

- Assign a Color for Status: An intact green seal means "fully stocked." A broken seal, or a temporary red seal, means "needs restocking."

By using color, you are adding a layer of immediate, intuitive data that the human eye can process much faster than text. This simple, low-cost strategy respects the valuable time of clinical staff and reduces the cognitive load of routine checks.

What is the Role of a Simple Log and Check Protocol?

You've implemented the perfect seals for each application, but without a documented process, there's no consistency. One nurse logs serial numbers, another doesn't, making the entire system unreliable.

A seal is only as effective as the protocol that governs its use. Implementing a simple, standardized log and check procedure ensures that all staff use the seals correctly, creating a reliable and defensible security system.

The best hardware in the world will fail if the software—your human process—is flawed. The seal is just the tool; the protocol is what puts it to work effectively. A successful protocol doesn't need to be complicated.

Core Elements of a Seal Protocol:

- The Check: At the start of every shift or during rounds, staff visually inspect the seal. Is it intact? If serialized, does the number match the log?

- The Action: If the seal is broken, the kit is immediately taken for restocking. If it's intact, no further action is needed.

- The Log: When a seal is broken for access (legitimately) or applied after restocking, it must be recorded.

- Simple Kits: A checkmark on a daily audit sheet may be enough.

- Controlled Substances: A detailed log entry (Date, Time, Name, Seal # Applied, Seal # Removed) is mandatory.

This documented process creates consistency. It ensures every team member understands their role, making the entire system of supply chain integrity robust and reliable.

Conclusion

Choosing the right seal in a clinical setting is a critical decision that balances access, accountability, and auditing. By matching the seal's design to the highest priority of the task, you directly enhance both patient safety and operational efficiency.

Find Your Perfect Balance with ProtegoSeal

From instant-access breakaway seals for crash carts to high-security serialized seals for drug cabinets, having the right tool is the first step. At ProtegoSeal, we provide a comprehensive range of clinical seals to meet your specific needs. Contact us to ensure your facility has the perfect seal for every application.