Your team spends hours manually scanning barcodes at the warehouse gate, creating bottlenecks. Worse, an asset goes missing mid-journey, and you have no data until it's too late, resulting in costly write-offs.

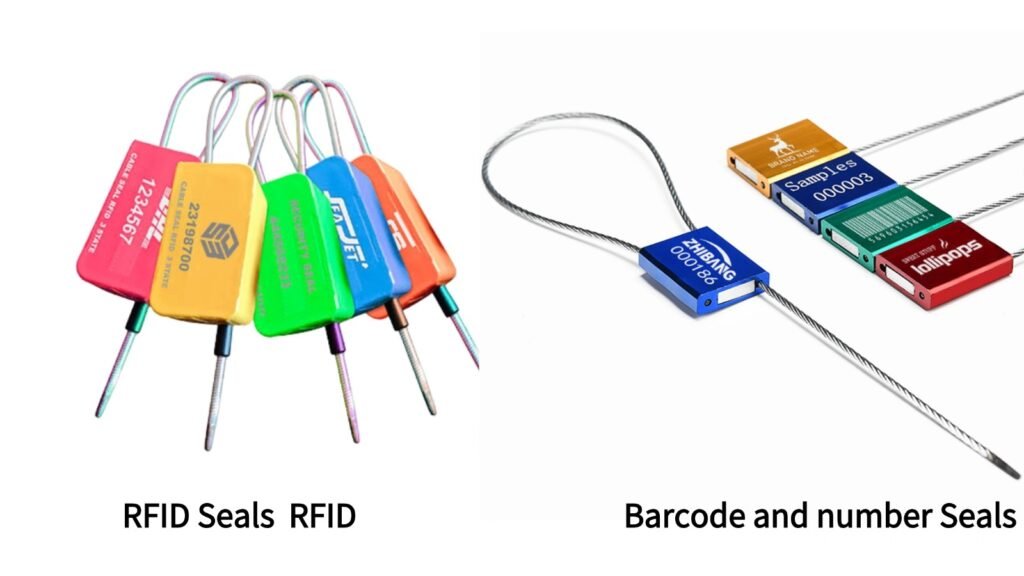

The right choice depends on your data needs. Barcode seals provide accurate point-in-time tracking at specific checkpoints. RFID seals offer continuous, automated real-time visibility throughout the entire logistics process, without needing manual line-of-sight scanning.

I’ve helped countless clients navigate this decision, and the most important thing I've learned is this: choosing between barcodes and RFID isn't a simple tech upgrade. It's a choice between two entirely different inventory management philosophies. The barcode seal is like a "periodic manual inventory"—you get a precise, accurate result at specific moments in time. The RFID seal is a "real-time dynamic inventory system," giving you constant knowledge of every asset's location and status. Your decision depends on whether you just need a final report, or if you need a tool that helps you manage the entire process.

Why Are Barcode Seals the Standard for Point-to-Point Tracking?

You need a reliable, low-cost way to track assets from your dock to your customer's dock. You're worried about the complexity and cost of adopting a whole new system.

Barcode seals are the established, cost-effective solution for checkpoint-based logistics. They provide a simple, highly accurate method for logging an asset's departure and arrival, confirming point-to-point integrity.

The barcode seal is the proven workhorse of the logistics industry for a reason. Think of it as your "end-of-quarter manual inventory." Its purpose is to give you a perfect, accurate snapshot of an asset's status at a specific moment—namely, when a person with a scanner points it directly at the seal. This method is built on the principle of line-of-sight scanning. The beauty of this system lies in its simplicity and low barrier to entry. Every smartphone can be a barcode reader, and the technology is universally understood. It provides an indisputable record that "Seal #12345 was scanned at Dock B on Tuesday at 2:15 PM." For companies whose primary need is to confirm departure and arrival, the barcode seal provides all the data they need with minimal investment and training.

How Do RFID Seals Enable Real-Time Visibility?

A critical pallet is missing from a 53-foot trailer, but paperwork shows it was loaded. Your team wastes hours manually searching, delaying the entire shipment and causing customer frustration.

RFID seals broadcast a unique ID that can be read automatically, from a distance, and without line-of-sight. This allows you to instantly verify a trailer's entire contents just by driving it through a portal, enabling true real-time asset visibility.

This is your "real-time dynamic inventory system." Unlike a barcode, an RFID seal doesn't need to be seen to be read. It uses radio waves to communicate. This fundamental difference unlocks a level of operational intelligence that barcodes simply cannot offer. Imagine installing RFID readers over your dock doors. Now, you don't need a person to scan anything. As the forklift drives onto the truck, the reader automatically logs that "Asset #67890 is now on Truck #42." When the truck leaves, the gate confirms all 150 assets are on board. If a pallet is left behind, the system flags it instantly. This is the power of automated data capture. It transforms your supply chain from a series of blind spots between manual scans into a continuously monitored glass pipeline. You're not just getting a report; you're managing the process live.

What Are the Differences in Speed, Data, Security, and Cost?

You're stuck trying to weigh the upfront cost of RFID against the long-term labor costs of barcodes. The choice feels overwhelming because the trade-offs aren't immediately clear.

The decision hinges on a trade-off: Barcodes have a lower initial cost but higher operational labor costs. RFID has a higher initial cost but delivers massive gains in scanning speed and data richness.

Let's break this down into a head-to-head comparison. I use this table to help clients clarify where the true value lies for their specific operation. This isn't about which is "better," but which profile fits your business needs.

| Feature | Barcode Seals ("Manual Inventory") | RFID Seals ("Dynamic System") |

|---|---|---|

| Speed | Slow. Requires one-by-one, line-of-sight manual scanning. Prone to bottlenecks. | Extremely Fast. Scans hundreds of seals per second automatically, without line-of-sight. |

| Data | Point-in-time data. "What was here at 2:15 PM?" | Continuous data stream. "What is here right now, and what just left?" |

| Security | Good integrity. The seal is tamper-evident, but data relies on manual process discipline. | Excellent integrity. The RFID tag can be encrypted and linked to the seal's physical state. |

| Cost | Low initial cost (seals are cheap, scanners are ubiquitous). High long-term labor cost. | High initial cost (seals, readers, software). Low long-term labor cost. |

I once worked with a large distribution center that was losing 1-2% of its inventory annually to simple mis-shipments. The cost of manual scanning was high, but the cost of the errors was even higher. After implementing an RFID system at their dock doors, their shipping accuracy went to 99.9% within six months. The system paid for itself in recovered assets and reduced labor in under a year.

What Are the Infrastructure and Software Requirements?

You're excited by the idea of real-time visibility, but you're worried about the hidden technical challenges. What else do you actually need to buy and install to make it work?

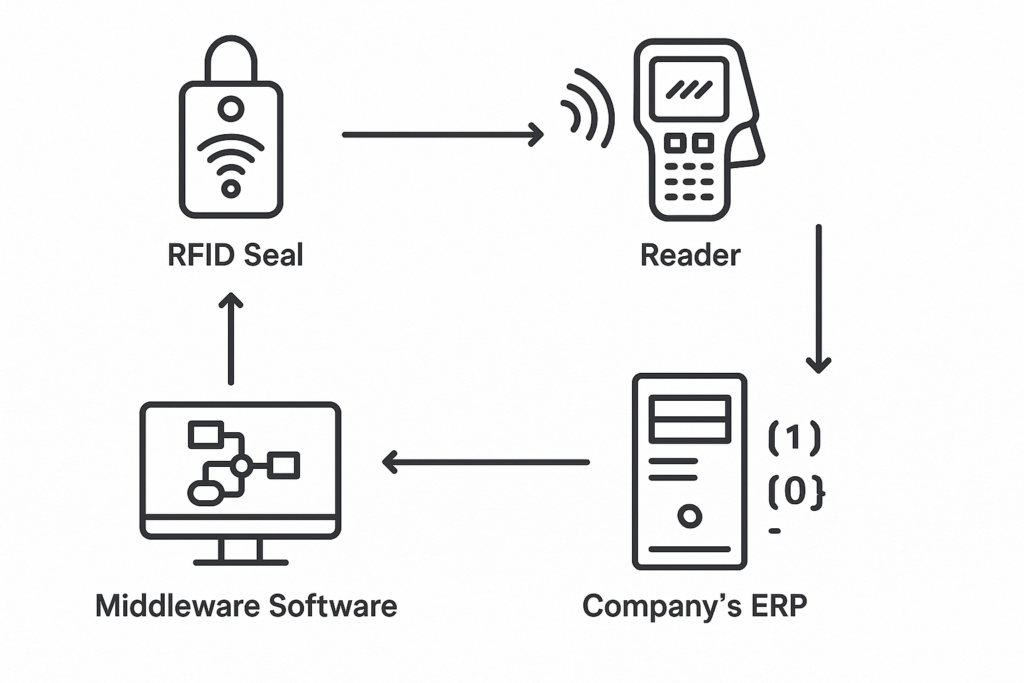

Implementing RFID is more than just buying seals; it requires fixed or handheld readers, antennas, and, most importantly, software to interpret the data and integrate it with your existing systems.

This is where the "real-time system" requires a real investment. While a barcode system can run on a simple spreadsheet, an RFID system is a more complex ecosystem.

Barcode System Infrastructure:

- Hardware: Handheld barcode scanners or smartphones with a camera.

- Software: A basic inventory application or even Excel. The logic is simple.

RFID System Infrastructure:

- Hardware:

- RFID Readers: These are the brains of the operation. They can be fixed portals (for dock doors), or handheld devices for spot-checks.

- Antennas: These broadcast the radio waves and listen for the seals' responses. Proper placement is critical for good read rates.

- Software:

- Middleware: This is crucial software that filters the raw data from the readers. It cleans up duplicate reads and makes the data usable.

- Integration: The middleware then needs to connect to your brain—your Warehouse Management System (WMS) or Enterprise Resource Planning (ERP) system—to make the data actionable.

The good news is that modern RFID solutions are becoming more plug-and-play, but planning for this full infrastructure is essential for a successful project.

How Do You Choose the Right Technology for Your Operation?

You understand the pros and cons, but you need a clear path to a final decision. How do you apply this knowledge to your own unique supply chain challenges?

Make your decision based on your primary business need: Do you need to solve a specific checkpoint problem, or do you need to optimize an entire process flow?

Let's simplify this with a clear framework. Answer these questions about your operation to find your answer.

| Ask Yourself... | If You Answer "Yes"... | Then Your Priority Is... | The Right Choice Is Likely... |

|---|---|---|---|

| Is my primary goal to confirm departure and arrival for simple shipments? | Yes | Point-in-Time Proof | Barcode Seals |

| Is my operational budget for new technology highly constrained right now? | Yes | Low Upfront Cost | Barcode Seals |

| Do I need to scan hundreds of items very quickly (e.g., full trailer loads)? | Yes | Speed & Throughput | RFID Seals |

| Do I suffer from losses or errors that happen between scanning points? | Yes | Real-Time Visibility | RFID Seals |

| Is improving labor efficiency and automating data entry a major company goal? | Yes | Process Automation | RFID Seals |

If you answered "Yes" to the first two, you need a reliable reporting tool. Stick with the proven, cost-effective barcode. If you answered "Yes" to the last three, you need a process management tool. The investment in RFID will likely provide a strong return on investment (ROI).

Conclusion

The choice between barcode and RFID is a strategic one. Barcodes offer a simple, low-cost proof of activity at key points. RFID provides a complete, real-time view of your entire operation, offering unparalleled speed and data.

Build Your Ideal Inventory System with ProtegoSeal

Whether you need a simple "manual inventory" approach or a sophisticated "real-time dynamic system," the right seal is the foundation. At ProtegoSeal, we offer both high-quality barcode and advanced RFID seals to fit your unique strategy. Contact us to discuss which philosophy is right for you.