You're using metal seals on all your trucks, thinking "stronger is better." But you're overspending and missing key tamper evidence. Or you're using plastic everywhere and risking major losses on high-value loads.

The choice between metal and plastic strap seals depends on your security goal. Metal seals act as a physical barrier to deter and delay thieves. Plastic seals offer superior, instant tamper evidence to prove an intrusion occurred.

After years of advising fleets, I've realized this "metal vs. plastic" showdown is really about deciding which kind of security expert you want to hire. It's a strategic choice. The metal seal is your "Bodyguard," whose job is physical deterrence and delay. The plastic seal is your "Investigator," whose job is to provide 100% accurate evidence of a breach. Your choice depends entirely on whether your security strategy focuses on "prevention" or on "proof." Let's break down who to hire for which job.

How Do Metal Strap Seals Provide Unmatched Barrier Strength?

Your trailer is carrying $500,000 worth of electronics. A flimsy seal is an open invitation for a coordinated, brute-force attack, leaving your cargo completely exposed.

Metal strap seals are physical barriers. Constructed from tin-plated steel, they require bolt cutters or heavy-duty tools to remove, creating a powerful deterrent and actively delaying any theft attempt.

This is where you hire the "Bodyguard." Its primary function is to be a visible, intimidating deterrent. When a potential thief sees a heavy-gauge metal seal, they know they can't get in quickly or quietly. This changes their risk calculation. This physical security aspect is crucial for high-risk scenarios.

The Bodyguard's Role:

- Deterrence: The imposing look of steel discourages opportunistic, low-effort attacks.

- Delay: Cutting through a metal seal takes time and requires specific tools. This delay can be enough to expose the thief or thwart the attempt altogether.

- Compliance: For programs like C-TPAT, using a barrier seal is often mandatory for cross-border shipments. A strong metal strap seal often meets or exceeds these security requirements.

I always recommend metal seals for shipments where the value of the cargo is high or the route passes through high-risk areas. You're not just sealing a door; you're hardening a target.

Why Do Plastic Strap Seals Offer Superior Tamper Evidence?

Your driver makes multiple stops. A seal is found broken at the final destination, but it's impossible to know which stop the theft occurred at or if the seal was manipulated before being broken.

Plastic strap seals are designed to be sensitive indicators. Any attempt to twist, cut, heat, or force them will cause the plastic to "blush" (turn white), stretch, or break cleanly, providing immediate and undeniable proof of tampering.

This is the "Investigator's" specialty: finding the truth. While a plastic seal can be broken by hand or with a simple cutter, its real value is not in its strength, but in its inability to hide tampering. It's designed to be a one-time-use witness. The polypropylene plastic used in most strap seals has a very clear material memory.

The Investigator's Evidence:

- Stress Marks (Blushing): If someone tries to twist or bend the seal to defeat the lock, the plastic visibly whitens. This evidence cannot be erased.

- Clean Break: Unlike metal, which can be bent, a plastic seal under sufficient force will snap. This provides a clear indication that a breach occurred.

- Heat Sensitivity: Trying to melt and re-fuse a plastic seal leaves obvious signs like discoloration and rough texture.

For Less-Than-Truckload (LTL) carriers or any multi-stop delivery route, the plastic seal is invaluable. It provides a definitive answer to the question, "Was this compartment secure when it left my possession?"

How Does the Break Strength Test Quantify the Difference?

You read "high-strength" on a seal's spec sheet, but what does that number actually mean in the real world? This ambiguity makes it hard to match a seal to your actual security needs.

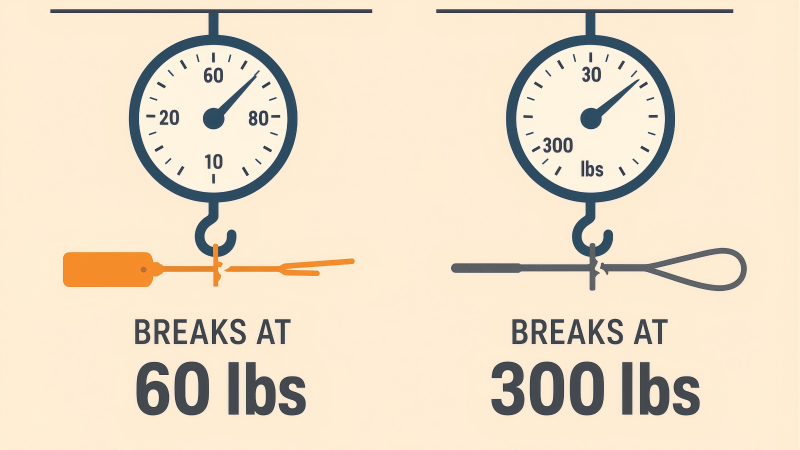

Break strength is a lab-tested measurement of the force required to break a seal. A typical plastic strap seal may break at around 50-75 lbs of force, while a metal seal can require over 250 lbs.

Understanding break strength helps you move from a vague sense of security to a data-driven decision. It's a critical part of risk management.

A Practical Comparison:

| Seal Type | Typical Break Strength | Removal Method | Real-World Implication |

|---|---|---|---|

| Plastic Strap Seal | 50-75 lbs (22-34 kg) | By hand, simple cutters. | Proof of entry is the goal. Can be removed quickly in a fast-paced environment. |

| Metal Strap Seal | 250+ lbs (113+ kg) | Bolt cutters, tin snips. | Delay and deterrence are the goals. Requires tools and effort to defeat. |

I once had a client in the garment industry who was losing individual boxes from multi-stop routes. They were using metal seals. Drivers had to wait for someone with bolt cutters at each stop, slowing down operations. We switched them to numbered plastic seals. Drivers could break them by hand at each stop, and the log of seal numbers proved which segments of the journey were secure. The losses stopped, and efficiency skyrocketed. They didn't need a bodyguard; they needed an investigator.

What Are the Hidden Advantages of Plastic Strap Seals in Cost and Efficiency?

Your security budget is tight, and drivers complain that metal seals slow them down. You're stuck in a trade-off between security, cost, and operational speed.

Plastic strap seals offer significant advantages in cost per unit and removal time. They require no tools to remove, speeding up driver turnaround at delivery points and lowering the total cost of your security program.

When you look at the total cost of ownership, plastic seals often have a clear edge in many common logistics scenarios. It's not just about the price tag of the seal itself.

Total Cost Analysis:

- Unit Cost: Plastic seals are significantly cheaper to manufacture and purchase than their metal counterparts. For a large fleet using thousands of seals a year, this direct cost saving is substantial.

- Tool Costs: Metal seals require every truck or every delivery point to have a pair of bolt cutters. These tools get lost, stolen, or break, adding an indirect cost and a point of operational failure. Plastic seals require zero tools.

- Labor & Dwell Time: This is the biggest hidden cost. A driver waiting for a tool to cut a seal is a driver not driving. This "dwell time" is a massive drain on efficiency. A plastic seal that can be snapped off by hand saves valuable minutes at every single stop. Over a year, this translates to thousands of hours of recovered productivity.

How Do You Choose Your Seal? A Scenario-Based Guide

The choice is a direct function of your cargo's value and your operational model. Match the seal's primary strength—barrier force or tamper evidence—to your biggest risk.

Let's make this simple. Here is the decision-making framework I walk my clients through. Find your scenario below to find your ideal security "hire."

Your Final Verdict:

| If Your Scenario Is... | Your Biggest Risk Is... | Your Strategy Should Be... | Your Ideal Seal Is... |

|---|---|---|---|

| Full Truckload (FTL), High-Value Cargo (e.g., electronics, pharma) | Targeted, forceful attack. | Prevention & Delay | Metal Strap Seal ("The Bodyguard") |

| Cross-Border Shipments (C-TPAT/AEO Routes) | Brute force & non-compliance. | Prevention & Compliance | Metal Strap Seal ("The Bodyguard") |

| Less-Than-Truckload (LTL) with multiple stops. | Undetected access at one stop. | Proof & Evidence | Plastic Strap Seal ("The Investigator") |

| General Freight, Domestic Routes (low to medium value) | Opportunistic theft & disputes. | Evidence & Efficiency | Plastic Strap Seal ("The Investigator") |

| Empty Trailer Repositioning | Unauthorized entry (stowaways, smuggling). | Low-Cost Evidence | Plastic Strap Seal ("The Investigator") |

Conclusion

The debate isn't about which seal is "best," but which security expert your cargo needs. By choosing between the "Bodyguard" (metal) for prevention and the "Investigator" (plastic) for proof, you create a smarter, more efficient, and cost-effective security strategy.

Hire the Right Security Expert with ProtegoSeal

Don't settle for a one-size-fits-all security plan. At ProtegoSeal, we provide both metal "Bodyguard" and plastic "Investigator" seals to match your specific needs. Contact us to build a security strategy that's both tough and intelligent.