You've sealed your trailer with a pull-tight seal, but cargo has vanished without a trace of tampering. This leaves you with unprovable losses and endless disputes with carriers and clients.

The fixed-length strap seal is the superior choice for truck trailers. Its unchangeable length makes it impossible to create "slack," a common trick used to bypass other seals, thus providing a definitive, tamper-proof closure.

I've learned from over a decade in this industry that the best security tools are the ones that remove human error. The reason the fixed-length strap seal is the go-to choice for truck trailers isn't because it's stronger or cheaper. It's because it represents the ultimate "fool-proof" and anti-fraud design. Its physical "immutability" completely eliminates the biggest security loophole caused by operator negligence, laziness, or even malice: Intentional Slack. The strap seal isn't just a lock; it's an engineered solution to a uniquely human problem.

What is the Core Principle of Fixed-Length Security Seals?

You think a seal is just a seal. But this misunderstanding ignores the crucial design differences that determine whether a seal is truly secure or just a piece of decorative plastic.

A fixed-length strap seal is a one-piece device with a single locking position. It cannot be adjusted. It is either securely locked at its designed length or it is broken.

The genius of the strap seal lies in its simplicity. Think of it as a metal or plastic strip with a locking head on one end and a specially designed tip on the other. Once that tip clicks into the locking mechanism, that's it. The loop has a fixed, predetermined circumference and cannot be tightened or loosened. This concept is known as tamper-evident design. It creates a binary state: secure or not secure. There is no in-between. Unlike other seals that can be applied loosely or tightly depending on the operator, the strap seal's design dictates the terms of its application. This forced consistency is its greatest strength, as it removes the variable of human judgment—and human error—from the security equation. It's a system designed for certainty.

How Do Strap Seals Eliminate the "Slack" Vulnerability?

The pull-tight seal was cinched tight when your container arrived, yet contents are missing. You're left confused, with no broken seal and no evidence for an insurance claim.

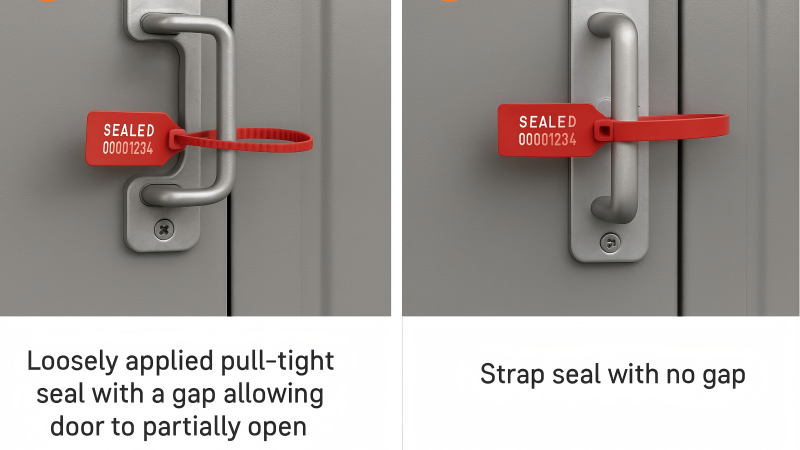

Strap seals defeat a common bypass method called "intentional slack." A pull-tight seal can be applied loosely, allowing doors to be opened and re-closed, then pulled tight to hide the tampering. A strap seal's fixed length makes this impossible.

This "slack" vulnerability is one of the most clever and frustrating bypass methods I've encountered. It's a form of insider fraud or opportunistic theft that leaves no evidence. Here’s how the crime works with a pull-tight seal: a dishonest operator intentionally loops the seal through the hasp but only pulls it through a few clicks, leaving a large, loose loop. This allows just enough slack to open one of the trailer doors, remove goods, and then re-close it. Afterward, they simply pull the seal to its tightest position. To a receiver, it looks perfectly secure. A fixed-length strap seal makes this impossible. Because it has only one locking position, the door hasps must be perfectly aligned for the seal to even be applied. There is no "loose" setting. By designing out the slack, you design out the crime.

Why Do Strap Seals Outperform Pull-Tight Seals for Truck Trailer Applications?

You use pull-tight seals for everything because they seem versatile. But for the specific geometry of a truck trailer hasp, this one-size-fits-all approach creates a critical point of failure.

On a truck trailer's locking bars, a strap seal provides a rigid, consistent closure. A pull-tight seal can allow dangerous movement and vibration, potentially weakening the seal or making tampering easier.

This is a matter of choosing the right tool for the specific job. A truck trailer's locking mechanism has a defined and consistent geometry. A fixed-length strap seal is engineered to match that geometry perfectly.

The Engineering Argument

| Feature | Fixed-Length Strap Seal | Adjustable Pull-Tight Seal |

|---|---|---|

| Fit | Snug, rigid fit. No movement. | Variable fit. Can leave a loop of slack. |

| Vibration | Resists vibration and jarring from road travel. | The loop can vibrate, potentially causing wear or damage over time. |

| Application | "Go/No-Go." It's either locked correctly or not at all. | Operator dependant. Can be applied incorrectly (too loose). |

| Tampering | Makes "shimming" and other manipulation difficult. | The loop can be a target for manipulation with fine tools. |

In my experience, the operational certainty of the strap seal is its biggest advantage. When a driver applies it, they don't have to wonder, "Is this tight enough?" The click of the lock is confirmation that the job is done correctly, every single time. This reliability is paramount in a high-volume, fast-paced logistics environment.

Beyond Security, What Is the Operational Efficiency of Adopting Strap Seals?

Your team wastes time with complex sealing procedures, and mistakes are common. The time lost and the cost of errors from using the wrong seals add up quickly.

Strap seals are faster to apply and easier to inspect than adjustable seals. Their simple, binary "locked/unlocked" nature speeds up both sealing and verification, improving driver turnaround and reducing inspection errors.

While security is the main goal, operational efficiency is a huge benefit that many fleet managers appreciate. The supply chain thrives on speed and accuracy. Slow, complex procedures cost money.

Time Savings during Application

A pull-tight seal requires an operator to thread the tail and then judge how tight to pull it. A strap seal is a simple "insert and click." This shaves seconds off every seal application, which adds up to significant labor savings across a large fleet.

Speed and Accuracy during Inspection

Inspecting a strap seal is instantaneous. Is it there and intact? Yes? Good to go. Inspecting a pull-tight seal requires a moment longer to check if it's truly tight or if there is hidden slack. In a busy distribution center or at a border crossing, these seconds matter. A simpler inspection process reduces the chance of human error and allows compliant drivers to get back on the road faster. This focus on "process-proofing" is a core principle of good fleet management.

How Do You Choose the Right Strap Seal: A Framework for Material and Break Strength?

You want to switch to strap seals, but the options—plastic, metal, different strengths—are overwhelming. Choosing the wrong one could mean you're either overspending or leaving your cargo under-protected.

Select your strap seal based on risk. For domestic, low-risk loads, a plastic seal offers clear tamper evidence. For high-value or cross-border shipments, a metal seal provides a stronger physical barrier.

Choosing the right strap seal is a straightforward risk assessment. You don't always need the most expensive option. The key is to match the seal's capabilities to the cargo's risk profile.

Here’s a simple framework I use to advise clients:

- Assess the Risk Level:

- Low Risk: Internal transfers, domestic shipments of low-value goods.

- Medium Risk: Standard commercial goods, domestic long-haul.

- High Risk: High-value goods (electronics, pharma), cross-border shipments, C-TPAT/AEO compliance routes.

- Match Material to Risk:

- Plastic Strap Seals: Ideal for low-risk applications. They offer excellent tamper evidence at a low cost. Their lower breaking strength is sufficient when the main goal is just confirming no one has opened the doors.

- Metal Strap Seals: The standard for medium-to-high risk. They provide both strong tamper evidence and a formidable physical barrier that requires a tool to cut. They are the go-to choice for most commercial trailer security.

- Consider ISO 17712 Compliance: For high-security international shipments, ensure the seal is classified as a barrier seal under ISO standards. This is often a requirement for customs programs.

Conclusion

The strap seal's fixed-length design is a deliberate choice for trailer security. It eliminates the risk of human error and intentional fraud, offering a simple, efficient, and uncompromisingly secure solution every single time.

Eliminate Slack and Secure Your Fleet with ProtegoSeal

Don't let "intentional slack" be the weak link in your supply chain. At ProtegoSeal, we provide high-quality, fixed-length strap seals designed to offer your fleet the ultimate fool-proof security. Contact us to find the perfect strap seal for your application.