Your tanker of high-value liquid arrives, but it's contaminated. A single drop of the wrong substance has ruined the entire load, creating a catastrophic loss far greater than simple theft.

A tanker seal is a specialized tool that protects against both theft and contamination. Unlike standard locks, it provides a tamper-evident guarantee of the cargo's purity and physical integrity—a crucial function for sensitive liquid and bulk goods.

Sealing a standard dry van is often just an anti-theft problem. But as I've learned from clients in the chemical and food-grade industries, sealing a tanker is like solving a complex chemistry and math problem. You're not just protecting quantity; you're safeguarding the cargo's precise chemical purity and physical integrity. Any failure on this front can lead to losses a hundred or even a thousand times greater than simple cargo theft. It's not just about locking a door; it's about preserving a specific, sensitive state from origin to destination.

What Makes a Tanker Truck Seal a Specialized Tool, Not Just a Lock?

You think any seal will do, treating your tanker like any other truck. This mistake exposes you to the unique and devastating risks of contamination, dilution, and product integrity failure.

A tanker seal must secure multiple access points—hatches and valves—and withstand sloshing and vibrations. It's a tool designed to prove that the product's quality and quantity have remained unchanged.

A tanker isn't a simple box. It's a mobile vessel with multiple entry points: top-loading hatches, bottom-discharge valves, and sampling ports. Each one is a potential point of failure.

I once worked with a client transporting cosmetic oils who faced a massive financial hit. It wasn't theft. Someone had added a lower-grade oil through an unsealed sampling port, contaminating a batch worth over $200,000. This is why tanker sealing is so specialized.

The seal's job is to create a tamper-evident shield around the entire vessel. It must prove that nothing was added and nothing was taken. It’s a guarantee of the product's precise state, which is a far more complex task than simply proving a door wasn't opened.

Key Differences: Dry Van vs. Tanker Sealing

| Feature | Standard Dry Van Truck | Tanker Truck |

|---|---|---|

| Primary Risk | Theft of goods. | Contamination, dilution, theft. |

| Sealing Points | One or two rear doors. | Multiple hatches, valves, and ports. |

| Value Protected | Value of physical items. | Value of product purity and quantity. |

| Seal's Function | Access control. | Product integrity assurance. |

For Liquid Cargo, Why Are Pull-Tight Seals the Industry Standard?

You need to seal a valve on a liquid tanker, but a heavy-duty seal is too rigid. Using the wrong seal leaves the valve partially unsecured, creating a vulnerability.

Adjustable pull-tight plastic seals are the standard because they can be cinched down snugly around valve handles and small hatches, leaving no space for manipulation. They are cost-effective for multiple-point sealing.

This is a classic case where "stronger" isn't "better." I often have to explain to fleet managers that a rigid bolt seal is useless on a valve. You need flexibility. For liquid tankers carrying products like fuel, milk, or non-hazardous chemicals, the pull-tight seal is the perfect tool. Its primary function is tamper evidence. It can be pulled to the tightest possible position around a valve handle or a small port lock. This lack of "play" is critical. It makes it impossible to partially open a valve to siphon off liquid or add a contaminant without breaking the seal. Since a single tanker can have more than 10 sealing points, the cost-effectiveness and ease of use of sequentially numbered plastic seals make them the ideal choice for this application. They provide a clear, low-cost "yes/no" answer to the question: "Has this access point been compromised?"

For Bulk Cargo, When Should You Choose High-Security Cable Seals?

You're hauling valuable bulk powder, and a simple plastic seal is broken. Thieves made off with a significant amount of product because the seal offered no physical resistance.

For high-value or hazardous bulk cargo like specialty chemicals, plastic pellets, or cement, a high-security cable seal provides both tamper-evidence and a strong physical barrier.

When the cargo itself is of extremely high value or is hazardous, you need to upgrade the security. Think of plastic pellets for manufacturing, which can be worth tens of thousands of dollars, or corrosive chemicals. Here, the risk of both theft and spillage is high. A cable seal is the right tool for this job. It offers a significant step up in physical strength from a plastic seal and is much more versatile than a bolt seal. Its flexible steel cable can be looped through hatches and locking bars of different sizes and configurations. We're moving from a simple tamper-evidence problem to a barrier-and-evidence problem. It requires wire cutters to remove, deterring opportunistic theft. Using a robust barrier seal like a cable seal sends a clear message that this cargo is of high consequence.

What Is the Dual Function: Preventing Theft and Ensuring Product Integrity?

You focus only on making sure the full quantity of liquid arrives. But the receiver rejects the entire shipment due to suspected contamination, and you have no evidence to prove otherwise.

A tanker sealing protocol's primary goal is ensuring product integrity. It provides proof against dilution, substitution, or contamination, which often represents a far greater financial risk than simple volume theft.

This is the central insight I share with all my clients in this sector. The seal is doing two jobs at once. For example, a driver might be tempted to siphon off 20 gallons of fuel. That's a direct, calculable loss. However, if that driver then adds 20 gallons of water to hide the theft, they have just destroyed the entire 8,000-gallon load. The loss is no longer the value of 20 gallons; it's the value of 8,000 gallons plus the cost of disposal and the damage to your company's reputation. The seal's real job is to act as a guarantee for the receiver. When they see an intact seal, they are not just confident the correct amount is there; they are confident the product is exactly what they ordered, with the correct purity and specifications. This is the "chemistry and math" guarantee that is indispensable.

What Is a Checklist for Implementing a Tanker Sealing Protocol?

Your drivers are inconsistently sealing tankers, leading to disputes and rejected loads. Without a standardized, mandatory process, your efforts are wasted and your liability is uncontrolled.

A successful protocol requires a clear "sealing diagram" for each tanker type, hands-on driver training, and a strict record-keeping process that logs every unique seal number.

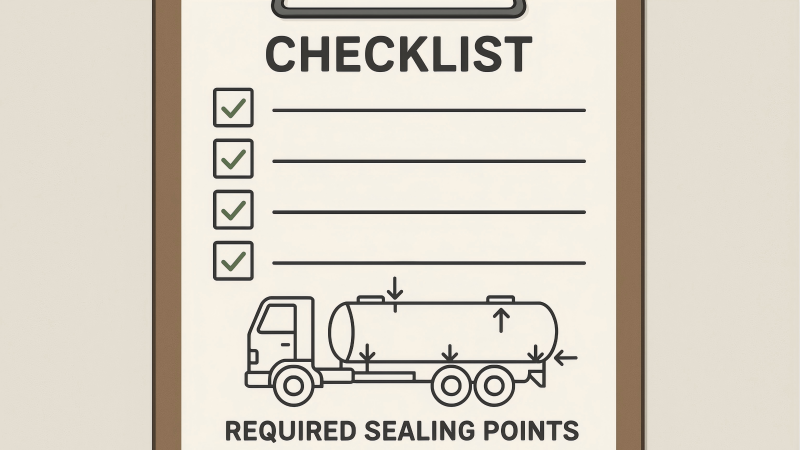

To make this work, you must remove all guesswork for your drivers. A vague instruction to "seal the truck" is a recipe for failure. A clear, documented protocol is essential. Here is a checklist I have developed with fleet managers to create a bulletproof system:

- Create a Sealing Diagram: For each type of tanker in your fleet, create a simple, visual diagram showing every single valve, hatch, and port that must be sealed.

- Establish a 2-Person Verification Process: At the loading facility, have one person apply the seals and a second person verify the seals are applied correctly and the numbers are logged. This eliminates single-person errors.

- Use a Seal Log: The log must document the unique serial number for each seal and its corresponding location on the tanker (e.g., Seal #12345 on "Discharge Valve 1," Seal #12346 on "Top Hatch 2").

- Train and Re-Train: Conduct hands-on training showing drivers and loaders the diagrams and the correct way to apply and check seals.

- Define the Receiving Protocol: Instruct receivers to verify every single seal against the seal log before unloading. Any discrepancy must halt the process and trigger an immediate report.

Conclusion

A tanker seal is a specialized application because it solves a different, more complex problem. It's not just securing a door against theft; it's a precision tool designed to guarantee product integrity across multiple access points, protecting your sensitive cargo from the catastrophic risks of contamination and dilution.

Master Your Bulk Cargo Security with ProtegoSeal

Protecting liquid and bulk cargo requires specialized tools and expertise. At ProtegoSeal, we provide the specific seals and protocols to guarantee product integrity from end to end. Contact us to build a sealing strategy that safeguards your most sensitive shipments.