You're choosing between plastic seals, but do you know their locking mechanisms answer two entirely different security questions? Selecting the wrong one means you're defending against the wrong threat entirely.

The choice depends on your primary risk. A pull-tight seal answers, "Has this been loosened?" by eliminating gaps to prevent tampering. A fixed-length seal answers, "Has this been replaced?" by maintaining a constant geometric shape that is hard to replicate or substitute.

In my years of consulting, I've found the most critical question isn't "Which seal is stronger?" but "What is the most likely attack on my asset?" The mechanisms are designed for different battles.

The pull-tight seal is a sentry against internal tampering. Its mission is to remove every millimeter of slack, ensuring nothing can be slipped in or out. It guards against a subtle, loosening attack. The fixed-length seal, however, is a bastion against a total replacement attack. Its rigid, unchangeable loop is a unique geometric signature. A thief can't just tighten a new one to look the same; they must have an exact, pre-broken, or counterfeit replica. Your choice is a strategic one: is your greatest risk from internal manipulation or from a complete, deceptive replacement?

Inside the Pull-Tight Mechanism: A Visual Breakdown?

A pull-tight seal looks simple, like a common zip tie, but is its security just as basic? This assumption overlooks the clever, one-way mechanism that provides its unique security function.

A pull-tight seal's security lies in a flexible tail with ridges that passes through a chamber containing a locking jaw, typically a metal insert. The jaw's teeth grip the tail, allowing it to tighten but never loosen.

Let's dissect this mechanism to understand how it answers the question, "Has this been loosened?" Its entire design is focused on creating a variable, but irreversible, loop size.

The Serrated Tail

The long, flexible tail of the seal is lined with angled serrations or teeth. These are the points of contact for the lock. The material, usually nylon or polypropylene, is chosen for its flexibility and strength, allowing it to be cinched down around objects of various shapes and sizes. This adaptability is its key feature.

The One-Way Locking Chamber

This is the heart of the seal. Inside the plastic housing is a small, sharp piece of metal or hard plastic, known as the locking jaw or insert. As the serrated tail is pulled through, it glides easily over the angled jaw. However, any attempt to pull the tail back causes the jaw to bite deeply into the plastic, locking it permanently in place. This mechanism is purely focused on preventing any slack from being reintroduced into the loop. Once that gap is closed, it stays closed.

The Anatomy of a Fixed-Length Seal's Locking System?

Does a fixed-length seal's security seem less impressive because it doesn't tighten? This misses the point. Its strength comes from its predictable, unchanging shape, creating a different kind of lock.

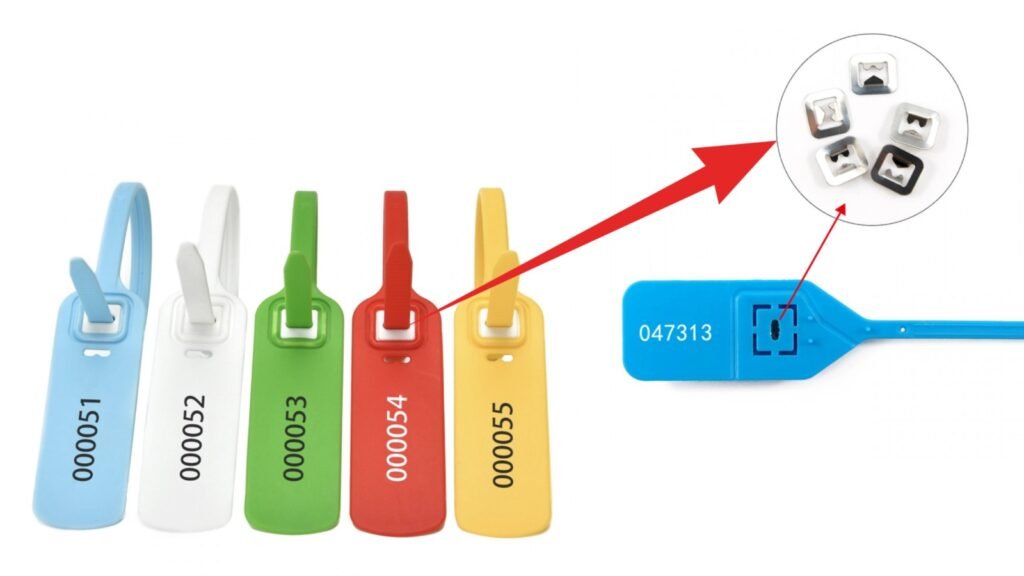

The fixed-length seal operates on a "click-lock" principle. A uniquely shaped plug on one end is pushed into a matching receptacle on the other until it clicks. Internal components then lock it, creating a fixed-size loop.

This mechanism is designed to answer the question, "Has this been replaced?" Its security is rooted in its consistent and difficult-to-replicate geometry.

The Unchanging Loop

Unlike the pull-tight, a fixed-length seal has a predetermined loop size. This consistency is a critical security feature. When you record that a specific fixed-length seal is on a container, you know exactly how it should look and fit. There is no variation, which makes spotting a substitution much easier for inspectors.

The "Click-Lock" Core

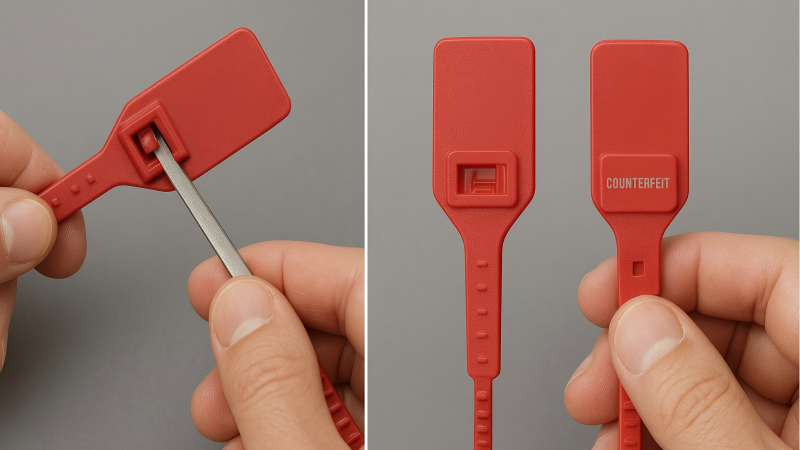

The magic happens when the two ends meet. One end has a carefully molded plug, and the other has a chamber designed to receive it. As the plug is inserted, it forces its way past one-way plastic or metal tabs. Once it passes a certain point, these tabs spring back into place, locking behind a ridge on the plug. It cannot be pulled out without destroying the seal's housing, leaving obvious signs of tampering. The goal is not to be tight, but to be a single, solid, verifiably authentic piece.

Security: Tamper-Resistance of Each Mechanism?

Are both mechanisms equally secure against attack? No. They are vulnerable to different methods of tampering, directly related to the unique security question each is designed to answer.

Pull-tight seals are more vulnerable to subtle bypassing of the loop, while fixed-length seals are more vulnerable to a full replacement attack if not properly customized and tracked.

Understanding these vulnerabilities is key to choosing the right defense. I always advise clients to "war game" the potential threats to their specific assets.

| Mechanism Type | Primary Security Goal | Vulnerability to Internal Tampering | Vulnerability to Replacement Attack | Best Defense Strategy |

|---|---|---|---|---|

| Pull-Tight Seal | Eliminate Gaps/Slack ("Has it been loosened?") | Higher risk if not pulled completely tight. A loose seal could potentially be manipulated. | Lower risk, as tightening a new seal to the exact same length is difficult. | Pull the seal as tight as physically possible. Leave no usable slack. |

| Fixed-Length Seal | Maintain Geometric Shape ("Has it been replaced?") | Very low risk. The fixed loop offers little room for manipulation of the contents. | Higher risk if the seal is generic. A thief could replace it with an identical, uncustomized seal. | Use seals with unique serial numbers, logos, and colors. Maintain a strict audit trail. |

Application Matching: Choosing the Right Mechanism for Your Needs?

So, how do you decide which locking mechanism is right for your operation? The choice becomes simple when you stop looking at the seal and start looking at what you are securing.

Choose a pull-tight seal for items that can be compressed or have variable sizes, like bags. Choose a fixed-length seal for applications with fixed locking points, like container latches or utility meters.

Let's apply the core insight to real-world scenarios. Your choice should be dictated by the primary risk you need to mitigate.

When to Use a Pull-Tight Seal (Guarding Against Loosening)

The greatest strength of the pull-tight is its ability to conform and eliminate space.

- Cash-in-Transit Bags: The goal is to cinch the bag's zipper so tight that no one can slide it open even a little. The risk is internal access.

- Fire Extinguishers: The seal ensures the safety pin hasn't been pulled and replaced. It's not about the extinguisher being stolen, but about it being partially used or tampered with.

- Airline Catering Trolleys: Often, these use pull-tights to secure canvas doors or zips, where any slack would be a critical vulnerability.

When to Use a Fixed-Length Seal (Guarding Against Replacement)

The strength here is the consistent, verifiable shape.

- Truck Trailers and Shipping Containers: The door latches have specific hasps. A fixed-length seal provides a snug but not tight fit. The main risk on a long journey is a seal being cut and replaced with a counterfeit one.

- Utility Meters: The dimensions of the lock point are standardized. A fixed-length seal provides a clear visual indicator that the original, utility-issued seal is still in place.

- Tote Boxes with Molded Holes: Many plastic distribution totes have two holes in the lid that line up. A fixed-length seal is the perfect "padlock" for this.

Beyond the Lock: Usability and Removal Considerations?

Is the security of the lock the only factor to consider? Not at all. A seal that is difficult to apply correctly or remove efficiently can create its own set of problems in a fast-paced operation.

Pull-tight seals are generally faster to apply to variable items but may require a cutting tool. Fixed-length seals are foolproof to apply to standard points and often have built-in break points for tool-free removal.

Efficiency and safety are also components of security. A seal that can't be used properly is not secure.

Application Speed and Ease

For a pull-tight seal, the operator needs to ensure they pull it completely tight. This takes a moment of focused effort. A fixed-length seal is simpler; you just push until it clicks. In high-volume environments like distribution centers, this can save significant time.

Removal Process

Consider who will be removing the seal and where. In a retail store, you might want a seal that an employee can break off by hand. Many fixed-length seals are designed with an intentional breakpoint for this purpose. A heavy-duty pull-tight seal used on a shipping container will almost always require a strong cable cutter, which is expected and part of the security protocol at a receiving warehouse. Choosing a seal that is too hard to remove can slow down operations, while one that is too easy can lead to accidental breakage.

Conclusion

Your choice of seal mechanism is a choice of security philosophy. Pull-tights guard against loosening by eliminating gaps, while fixed-length seals guard against replacement by maintaining a constant shape.

Match Your Security Strategy with ProtegoSeal

Whether your greatest risk is internal tampering or a complete replacement attack, using the correct seal mechanism is your first line of defense. At ProtegoSeal, we help you analyze your risks to select the perfect seal. Contact us to ensure you are answering the right security question for every application.