Choosing between Nylon and Polypropylene for a plastic seal feels like a minor detail, until a failed seal puts an entire high-value shipment at risk.

The material of your plastic seal—typically Polypropylene (PP) or Nylon (PA)—is a critical security variable. Nylon offers superior strength and temperature resistance for high-risk applications, while Polypropylene provides a cost-effective solution for controlled, low-risk environments.

When I'm advising clients on plastic seals, I often use a simple analogy. Polypropylene (PP) is like a reliable "family sedan." It's cost-effective and perfectly capable of handling the majority of daily, short-haul tasks in controlled environments. Nylon (PA), on the other hand, is an "armored car." You bring it in for the high-value, long-haul missions that pass through harsh, unpredictable environments. You choose the armored car not just because it's tougher, but because it maintains its integrity through extreme heat and cold. Critically, when it's attacked, it breaks cleanly, "shouting" the evidence of tampering loud and clear. For a domestic shipment, the family sedan is often enough. But for international trade where cargo is at sea for weeks, the extra cost of Nylon isn't for expensive plastic; it's the cheapest, most reliable "insurance" you can buy for your high-value goods.

Why Your Seal's Material is a Critical Security Decision?

Do you think "plastic is plastic" when it comes to security seals? This misconception ignores the fundamental science that dictates a seal's performance, leaving your cargo vulnerable to both tampering and environmental failure.

The specific polymer used determines a seal's breaking strength, its behavior in extreme temperatures, and—most importantly—how it reveals evidence of an attack. The wrong material can fail on its own or stretch ambiguously when tampered with.

A security seal has one primary job: to provide clear, undeniable evidence. This evidential value is directly tied to its material composition. I have seen cases where a cheap seal made of the wrong plastic became brittle in the cold and snapped during routine handling. In another instance, a seal elongated so much when pulled that a thief could access the goods and then push the seal back to a near-original position. In both scenarios, the chain of custody was compromised. One created a false positive for tampering, the other a false negative. The material isn't a minor detail; it is the very foundation of the seal's reliability as a silent witness.

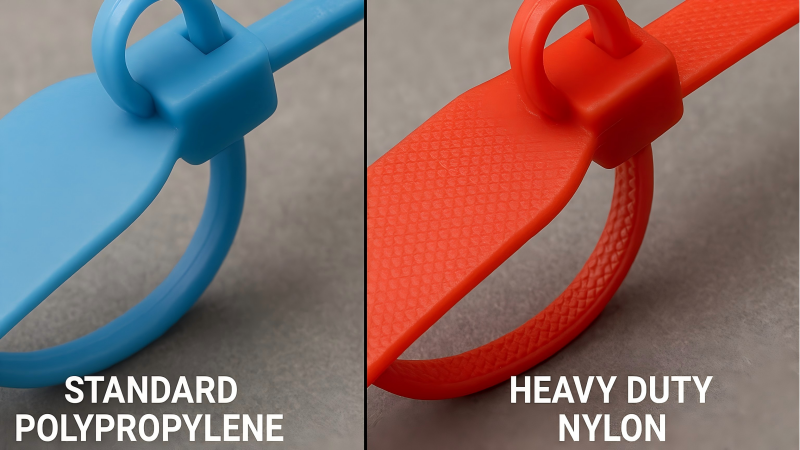

Polypropylene (PP): The Versatile Workhorse vs. Nylon (PA): The High-Strength Specialist?

Are you unsure whether to opt for the standard seal or the premium upgrade? This choice becomes simple once you understand the core identity of each material and the job it was designed to do.

Think of Polypropylene (PP) as your cost-effective "family sedan"—versatile and reliable for everyday, low-risk logistics. Nylon (PA) is your specialized "armored car"—built for superior strength, toughness, and performance in harsh, high-risk environments.

Understanding these two materials is like a fleet manager understanding their vehicles. You wouldn't send a city car on a long-haul arctic route, and you don't need an armored truck for a local delivery.

The Polypropylene (PP) Profile: The Family Sedan

- Identity: The general-purpose workhorse.

- Key Strengths: Excellent cost-effectiveness, good flexibility, and resistance to acids and bases. It's the go-to material for the majority of domestic shipping and routine logistics where conditions are predictable.

- Primary Use: High-volume applications like retail totes, local courier bags, and fire extinguishers.

The Nylon (PA) Profile: The Armored Car

- Identity: The high-performance specialist.

- Key Strengths: Superior tensile strength, exceptional durability across a wide temperature range (especially cold), and excellent abrasion resistance. It provides clear evidence of tampering by breaking cleanly under extreme force.

- Primary Use: High-value international shipping, airline carts, cash-in-transit containers, and any long-haul route with temperature extremes.

The Ultimate Showdown: Nylon vs. PP Across 5 Key Performance Metrics?

Need to make a data-driven decision? Breaking down the comparison into key metrics reveals a clear picture of when the extra investment in Nylon pays for itself.

Let's compare them across tensile strength, temperature range, flexibility, moisture sensitivity, and cost. Nylon consistently outperforms in strength and temperature stability, justifying its higher cost for demanding journeys.

Analogies are useful, but numbers make the final decision. When I walk clients through a technical comparison, these five points are what truly matter.

| Metric | Polypropylene (PP) - "Family Sedan" | Nylon (PA) - "Armored Car" | Why It Matters for Security |

|---|---|---|---|

| 1. Tensile Strength | Good (Avg. 15-20 kgf) | Excellent (Avg. 30-50 kgf) | Higher strength requires more force to defeat, deterring opportunistic theft. Nylon is simply much harder to break. |

| 2. Temperature Range | Fair (-20°C to 80°C) | Excellent (-40°C to 120°C) | Nylon remains strong and ductile in deep cold where PP can become brittle. This is critical for winter or refrigerated transport. |

| 3. Flexibility | High (stretches before breaking) | Lower (more rigid, breaks cleanly) | Nylon provides clearer evidence. PP can stretch, creating ambiguity. Nylon's clean break is a loud, clear "shout" of tampering. |

| 4. Moisture Sensitivity | Very low | Moderate (absorbs moisture) | PP is better for very humid environments. Nylon's strength can be slightly reduced by moisture, a factor to consider in design. |

| 5. Material Cost | Lower | Higher | PP is the economical choice for high-volume, low-risk use. Nylon's cost is an investment in security for high-value assets. |

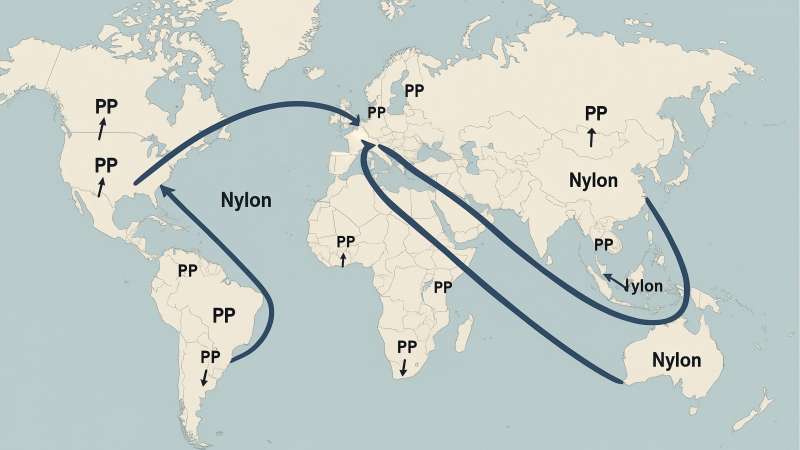

Application Blueprint: When to Use PP and When to Demand Nylon?

How do you translate this technical data into a real-world purchasing policy? It comes down to creating clear guidelines based on the value of goods and the risks of the journey.

Use Polypropylene (PP) for domestic, short-haul, and high-volume logistics in controlled climates. Mandate Nylon (PA) for international shipments, high-value goods, and any route that involves temperature extremes or long periods without supervision.

Here is the blueprint I provide to my clients. It's a simple, risk-based approach to seal selection that removes guesswork.

Choose Polypropylene (PP) When:

- The shipment is domestic and short-haul (less than 48 hours).

- The value of the cargo in a single container is low to moderate.

- The route does not involve extreme cold or temperature swings.

- You are sealing thousands of items daily, such as retail totes or medical trays, and need a cost-effective solution.

Demand Nylon (PA) When:

- The shipment is international or will be in transit for several weeks.

- The cargo is high-value (pharmaceuticals, electronics, luxury goods).

- The transport route crosses cold climates or involves refrigerated containers ("reefers").

- You require the most unambiguous, legally defensible evidence of tampering for cash-in-transit or high-security applications.

Making the Right Call: A Quick Decision-Making Checklist?

Still on the fence? Running through a quick checklist can bring instant clarity and help you select the right material with confidence, ensuring your choice is both cost-effective and secure.

Answer these three simple questions about your shipment. If you answer "yes" to even one of them, the small additional investment in a Nylon seal is a necessary and prudent business decision.

Before you place your next order for plastic seals, ask yourself these questions about the application:

- Is the total value of the cargo I'm sealing greater than 1,000 times the cost of the seal itself?

- (If yes, you are protecting a high-value asset. Choose Nylon.)

- Will this seal be in transit for more than 48 hours or pass through temperatures below 0°C (32°F)?

- (If yes, you need superior durability and temperature resistance. Choose Nylon.)

- For legal or insurance purposes, do I need the clearest, most undeniable physical evidence of a tampering attempt?

- (If yes, you need the clean, brittle fracture of Nylon.)

If you answered no to all three, then a high-quality Polypropylene seal is likely a smart, cost-effective choice for your needs.

- (If yes, you need the clean, brittle fracture of Nylon.)

Conclusion

The choice between Polypropylene and Nylon is a calculated business decision. It's about how clearly you understand your cargo's value, the risks of its journey, and the potential cost of a security failure. Choose wisely.

Secure Your Supply Chain with Security Seals from ProtegoSeal

At ProtegoSeal, we provide high-quality, tamper-evident security seals that deter theft, ensure compliance, and provide irrefutable evidence. Contact us today and let ProtegoSeal help secure your supply chain with reliable security seal solutions!