Are you confused by terms like "ISO 17712 H Class" or "tensile strength"? This confusion isn't just academic; it can lead to buying the wrong product, resulting in catastrophic cargo loss or customs rejection.

Security seal terminology is the language of risk management. Understanding it transforms you from a simple purchaser into a security architect for your own supply chain, enabling you to make informed decisions that protect your bottom line.

The language of security seals is not industry jargon meant to confuse you. It is the language of risk management. Each term represents a critical decision point, with real financial and operational consequences behind it. A buyer who is fluent in this language is no longer just a procurer of parts; they become the architect of their own supply chain's security. My goal with this glossary is not for you to memorize words, but for you to learn to speak a professional language of "trust and verification."

The Fundamentals: Key Terms for Security Ratings and Strength?

Do you feel like terms such as "indicative" or "high-security" are just marketing buzzwords? Without a clear definition, you can't properly assess a seal's true capability, leaving your assets vulnerable.

These terms define a seal's core mission. Indicative seals provide evidence, while high-security seals provide a physical barrier. Understanding this distinction is the first and most critical step in designing a layered security plan.

Let's start with the foundational vocabulary. These words define the security seal's basic job description and its physical resilience. They tell you whether the seal is designed to be a "witness" or a "guard." Misunderstanding these fundamentals is like trying to build a house without knowing the difference between a wooden frame and a steel beam. Both are useful, but for entirely different jobs. Mastering these terms allows you to start building your security strategy on a solid foundation, matching the right level of physical defense to the specific risk you're trying to mitigate.

| Term | Definition | Why It Matters to a Buyer |

|---|---|---|

| Indicative Seal | A seal designed to show evidence of tampering (to indicate entry), but which can be removed by hand or with a simple tool. | This is your "witness." Perfect for internal controls and low-risk scenarios where information is more important than a physical barrier. |

| High-Security Seal | A barrier seal made of metal, designed to act as a physical obstacle and require a substantial tool (like bolt cutters) for removal. | This is your "guard." Essential for high-value cargo and international shipping where active deterrence is the primary mission. |

| Tensile Strength | The amount of pulling force a seal can withstand before it breaks. It is measured in pounds or kilograms. | This tells you how resistant the seal is to being pulled apart. It's a key indicator of its overall strength and quality. |

| Shear Strength | The amount of force a seal can withstand from a cutting action, like from bolt cutters or shears. | This a critical metric for high-security seals, as it directly relates to how difficult it is for a thief to physically cut the seal off. |

Navigating Global Trade: Essential Compliance and Standards Terminology?

Are you worried that a simple seal choice could get your shipment impounded by customs for weeks? This is a valid fear for any global shipper, and it almost always comes down to misunderstanding compliance terms.

Compliance terms are non-negotiable rules for international trade. Terms like ISO 17712 and C-TPAT aren't suggestions; they are requirements that act as your passport for crossing borders smoothly.

This is the language of international law and order. For a global buyer, these are the most important terms in the entire glossary. A failure to understand and adhere to these standards can have immediate and severe financial consequences, including crippling delays, hefty fines, and even the loss of "trusted shipper" status. Think of these terms not as product features, but as unbreakable rules of the road for the global supply chain. They are the external requirements that will often dictate the minimum level of security you must employ, forming the foundation of your high-risk security protocols.

| Term | Definition | Why It Matters to a Buyer |

|---|---|---|

| ISO 17712 | The global standard specifying the procedures for classifying and managing security seals. An "H" Class rating signifies a high-security seal. | This is the world's benchmark for seal strength. If you ship internationally, you must use a seal certified to the ISO 17712 "H" Class standard. No exceptions. |

| C-TPAT | The Customs-Trade Partnership Against Terrorism, a U.S. Customs and Border Protection (CBP) program that requires high-security seals. | If you ship to the USA, C-TPAT compliance is mandatory. Using a non-compliant seal is a direct violation that will flag your shipment. |

| Annex A | The part of the ISO 17712 standard that audits a manufacturer's internal security processes, like how they control serial numbers. | This is how you verify your supplier's integrity. A certified seal from a manufacturer that fails an Annex A audit is a major red flag. Always ask for proof. |

The Anatomy of a Seal: Glossary for Physical Properties and Construction?

Do you think a lock is just a lock? The specific design and construction of a seal's components are what separate a truly secure device from one that only looks secure but can be easily defeated.

Understanding security seal's anatomy helps you identify its vulnerabilities and strengths. Features like an anti-spin mechanism are not minor details; they are specific countermeasures against known tampering techniques.

Now we move from the "what" to the "how." These terms describe the physical engineering of the seal itself. As an architect of your supply chain's security, you need to know how your tools are built. Is the locking mechanism easily bypassed? Can the seal be manipulated without breaking? Answering these questions allows you to assess the real-world resilience of a seal beyond what's written on the spec sheet. It's the difference between buying a car based on the color versus understanding the engine, transmission, and safety features. This knowledge empowers you to ask suppliers the right questions and spot a weak design.

| Term | Definition | Why It Matters to a Buyer |

|---|---|---|

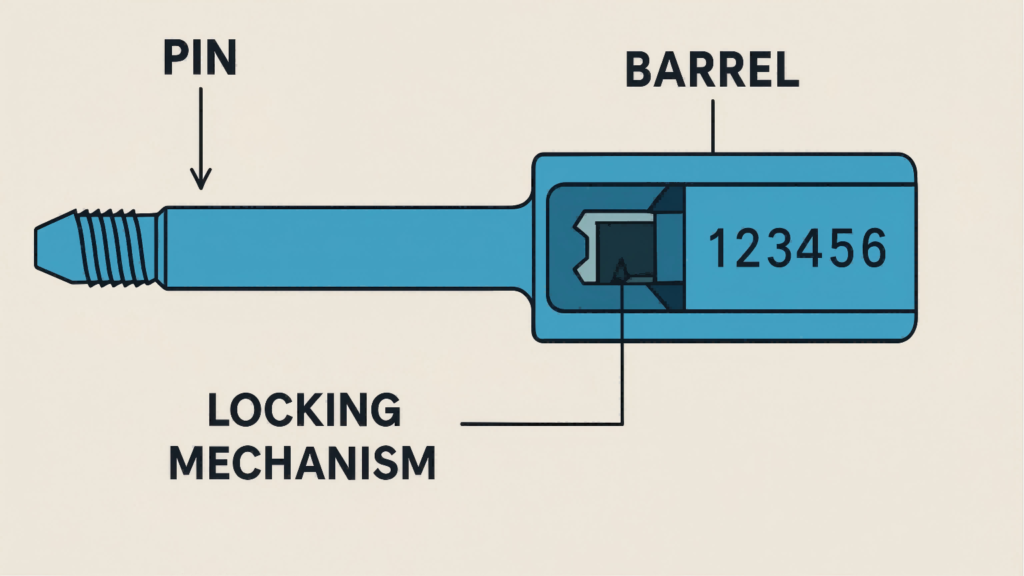

| Locking Mechanism | The internal component that engages to secure the seal. This can range from a simple plastic clip to a complex series of metal rings. | This is the heart of the seal. A weak or easily defeated locking mechanism renders the entire seal useless, no matter how strong the rest of it is. |

| Anti-Spin | A design feature in high-security bolt seals that prevents the pin and barrel from being spun at high speed with a drill. | This is a direct countermeasure to a common tampering method where friction and heat are used to defeat the lock. It's a crucial security feature. |

| Barrel & Pin | The two main components of a bolt seal. The pin is inserted into the barrel to lock it. | The material and construction of these two parts determine the seal's brute-force strength. They must both be made of hardened steel for high security. |

Making Your Mark: A Guide to Customization and Identification Terms?

Is a seal just a physical barrier, or is it a data point? If your seal isn't uniquely marked and tracked, it's failing at its most basic job: providing information and evidence.

Customization and identification terms are about transforming a generic seal into a unique "digital fingerprint" for your shipment. A unique serial number turns a piece of plastic or metal into a trackable asset.

This is the language of identity and traceability. A blank, unnumbered seal provides almost no security value because it can be easily replaced. The terms in this section are what give a seal its voice, allowing it to "testify" in your chain of custody. As a buyer, your decisions here directly impact how well the seal integrates into your operational workflow. Will you scan a barcode for efficiency? Will you use a custom color for easy visual identification? This is how you tailor the product to fit your unique process, turning it from a simple lock into an integrated part of your management system.

| Term | Definition | Why It Matters to a Buyer |

|---|---|---|

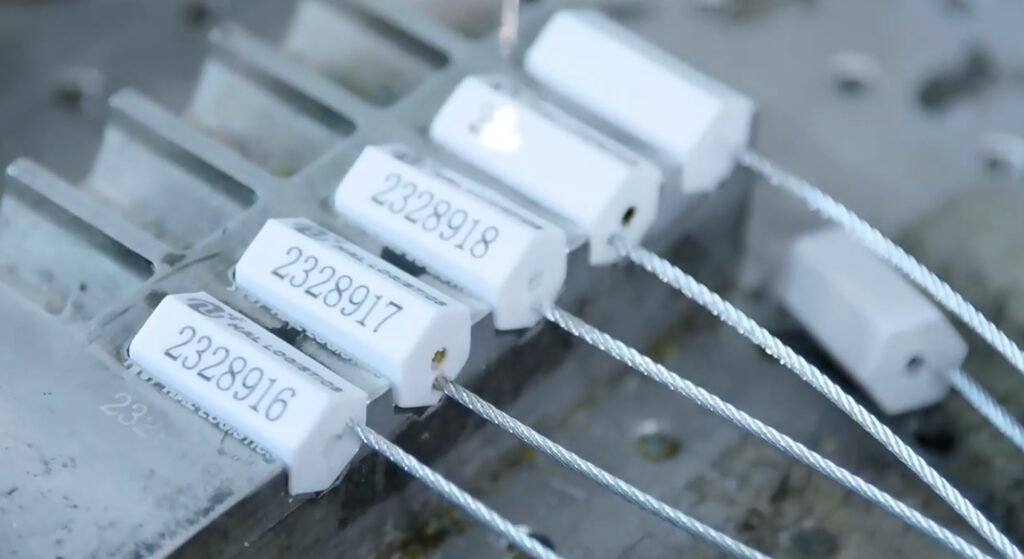

| Serial Number | A unique, sequential number printed on every individual seal. | This is the single most important feature for tamper evidence. Without a unique number, you cannot prove a seal has been replaced. |

| Barcode / QR Code | A scannable code that contains the serial number and other data. | This dramatically improves accuracy and efficiency in your logging process, reducing the risk of human error when recording seal numbers. |

| Laser Engraving | A method of marking the seal using a high-powered laser, which is permanent and cannot be removed or altered. | This is the most secure marking method. It ensures the serial number cannot be tampered with, unlike surface-level hot stamping which can sometimes be scraped off. |

From Product to Process: Terminology for Seal Application and Management?

Have you invested in the best seals on the market, only to have your staff apply them incorrectly? The world's greatest seal is useless if it's not supported by a robust process.

The terminology of process and management describes the human side of security. A Seal Protocol is the set of rules that brings the physical seal to life, ensuring it is used correctly and consistently every time.

We end with the most important part: the language of action. A seal sitting in a box does nothing. Its value is only unlocked through a strict and well-defined process. As the architect, you must design this process. How are seals stored? Who is authorized to apply them? How are numbers recorded? How is a broken seal investigated? These terms define the system within which your seals operate. Without a strong process, even the most expensive seal is just a decoration. This is where you truly implement the philosophy of "trust, but verify" and create a culture of security throughout your organization.

| Term | Definition | Why It Matters to a Buyer |

|---|---|---|

| Chain of Custody | The chronological documentation showing the seizure, custody, control, transfer, analysis, and disposition of physical or electronic evidence. | Your seal is a key link in this chain. A documented seal log proves the chain of custody was maintained, which is critical for insurance claims and legal disputes. |

| Seal Protocol | Your company's specific, step-by-step procedure for the application, verification, documentation, and removal of seals. | This ensures consistency and eliminates guesswork. A strong protocol is your best defense against both external threats and internal errors. |

| Seal Log | A physical or digital record of every seal used, including its serial number, date, time, location, and the person who applied it. | "If it's not written down, it didn't happen." The seal log is your primary evidence that your protocol was followed. It is an essential and non-negotiable document. |

Conclusion

Mastering security seal terminology is not about memorizing words. It's about learning the language of risk management, empowering you to architect a truly secure and efficient supply chain.

Speak the Language of Security with ProtegoSeal

Ready to move from purchaser to architect? The experts at ProtegoSeal speak your language. We can help you translate your security needs into a robust, cost-effective sealing solution. Contact me for a consultation.