Are you choosing a security seal based on the simple idea that metal is always stronger and therefore better? This common assumption can lead to costly mistakes, either by overspending on security or creating dangerous vulnerabilities.

The right choice isn't about strength, but about strategy. Plastic seals provide tamper evidence through information, while metal seals provide it through a physical barrier. The best security plans use both, each deployed for its specific mission.

In all my years advising clients, I've seen the same debate: plastic versus metal. But this debate is based on a false premise. Plastic and metal seals are not a weak option versus a strong option.

They are the products of two entirely different security philosophies. A metal seal, specifically a high-security bolt seal, is born from a "Fortress Philosophy." Its entire purpose is to be a physical barrier that provides deterrence. A plastic seal is born from an "Information Philosophy." Its purpose is to be a status indicator that provides tracking and evidence. A truly excellent security system isn't about choosing one; it's about knowing how to intelligently combine them at different points in your supply chain.

Plastic vs. Metal Seals: A Head-to-Head Comparison of Strengths, Applications, and Costs?

Are you struggling to articulate the real operational differences between a plastic and a metal seal beyond just their material? This lack of clarity can lead to inconsistent and ineffective security policies across your team.

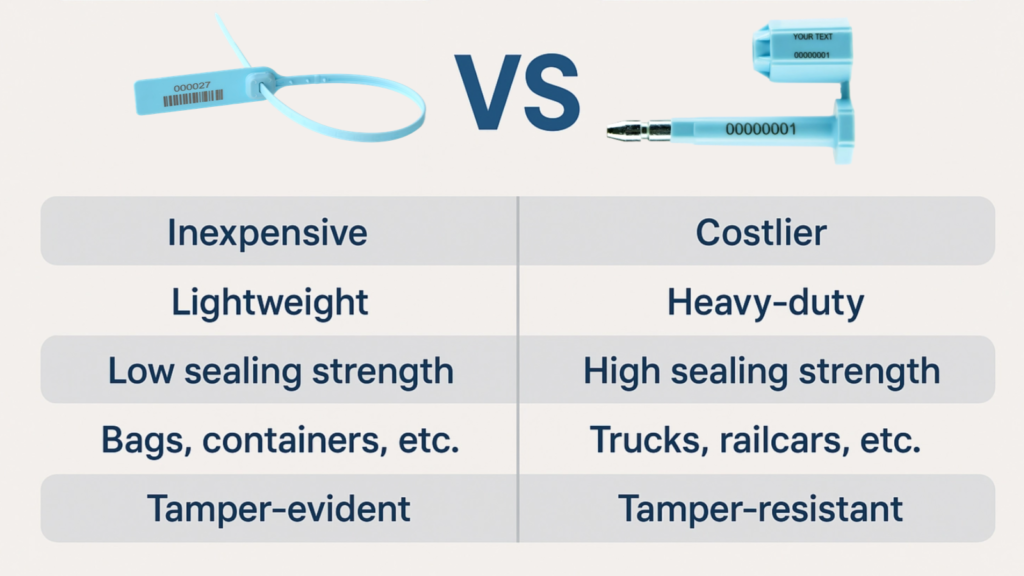

Plastic seals are low-cost, flexible indicators perfect for internal control and showing evidence. Metal seals are rigid, high-strength barriers designed for deterrence and high-risk shipments. Their applications, strengths, and costs reflect these fundamentally different roles.

To design a smart system, you must first understand your tools. This isn't just about what they are made of; it's about what they are made for. The Fortress Philosophy (metal) is about preventing an attack. The Information Philosophy (plastic) is about knowing an attack happened. Both are valid and essential; they just solve different problems. Looking at them side-by-side makes their distinct missions crystal clear and is the first step in moving from a simple buyer to a security architect for your own supply chain.

| Feature | Plastic Seals (Information Philosophy) | Metal High-Security Seals (Fortress Philosophy) |

|---|---|---|

| Primary Mission | Status Indication, Tamper Evidence | Physical Barrier, Active Deterrence |

| Material | Polypropylene, Nylon | Hardened Steel Pin & Barrel, ABS Plastic Coating |

| Removal | By hand or with simple cutting tool | Requires heavy-duty bolt cutters |

| Uniqueness | Unique Serial Number | Unique Serial Number |

| Best Use Case | Internal logistics, roll cages, fire extinguishers | International shipping, high-value cargo |

| Regulatory Role | Process control, internal audits | C-TPAT & ISO 17712 Compliance |

| Cost | Low | Moderate to High |

What Is the Mandatory Seal for International Shipping Containers?

Do you assume any strong-looking metal seal is good enough for your international shipments? This is a dangerous gamble that can result in your containers being stopped, inspected, and heavily fined at the border.

The only mandatory seal for international shipping containers under programs like C-TPAT is a high-security bolt seal or cable seal that is independently certified as ISO 17712 "H" Class compliant.

This is where the "Fortress Philosophy" is not just a choice; it's the law of the land for global trade. Customs authorities worldwide have standardized on ISO 17712 as the benchmark for a true physical barrier. An "H" Class rating means the seal has passed rigorous, third-party tests for tensile, shear, and impact strength. It is a verified fortress. A simple indicative plastic seal or a non-certified metal seal will be rejected by customs. I've seen companies suffer weeks of delays and thousands in fines because they tried to save a few dollars on a non-compliant seal. For any international container, there is no debate: a certified high-security barrier seal is the only option.

Beyond Brute Force: When a Plastic Seal Is the Smarter Choice?

Is your team using expensive, tough-to-remove bolt seals for every single application? This "more is more" approach is likely wasting significant amounts of money and creating unnecessary operational friction for your staff.

A plastic seal is the smarter choice for internal logistics, process control, and any scenario where the primary goal is information, not brute-force prevention. It provides verifiable tamper evidence at a fraction of the cost.

Let me give you a real-world example of the "Information Philosophy" in action. A large catering company was experiencing inventory shrinkage from their trucks. Their first instinct was to use heavy-duty seals. I told them this was overkill. The threat wasn't an external break-in; it was an internal process issue. We switched them to simple, low-cost plastic pull-tight seals with unique numbers. The new rule was simple: the kitchen logs the seal number out, and the event manager verifies that same number at the venue before breaking it. The shrinkage vanished in two weeks.

The plastic seal didn't physically stop anyone. It created a data trail. It provided information that enforced accountability. This is something an expensive metal seal couldn't have done better or more cost-effectively.

Your Selection Checklist: 3 Key Questions to Ask Before Choosing a Seal?

Feeling overwhelmed trying to decide between the two philosophies for each specific shipment? Without a consistent framework, your team is likely to make inconsistent, gut-feeling decisions that create risk.

To choose the right seal every time, you only need to answer three questions:

- What is the mission?

- What are the rules?

- What is the risk?

This simple checklist turns a complex decision into a clear choice.

Here's a breakdown of the framework I use with every client to build their security protocol:

- What is the Mission: Information or Fortress?

Are you trying to deter a break-in on a high-value load (Fortress), or do you need to know if a first-aid kit has been opened since its last inspection (Information)? Define the goal first. - What are the Rules: Is Compliance a Factor?

Is this shipment crossing an international border? Is it subject to specific industry regulations (like pharmaceuticals or hazardous materials)? If yes, your choice might be made for you. Compliance rules always demand a Fortress. - What is the Risk: What's the Financial Impact of a Breach?

If this container of consumer electronics is stolen, the loss is $250,000. That justifies the cost of a high-security Fortress. If a tote of linens is tampered with, the loss is minimal. An informational plastic seal is perfectly sufficient.

The True Cost of a Mismatch: How the Wrong Seal Impacts Insurance, Compliance, and Your Bottom Line?

Do you think the only cost of choosing the wrong seal is the price of the seal itself? This drastically underestimates the massive downstream financial consequences of a mismatched security strategy.

Using the wrong seal can lead to denied insurance claims, steep regulatory fines, lost contracts, and operational chaos. The cost of a mismatched seal isn't measured in cents, but in thousands or even millions of dollars.

I'll never forget a client who shipped a container of high-value machinery to Europe. To save a little money, they used a heavy-duty but non-certified metal seal instead of a proper ISO 17712 "H" class bolt seal. The container was flagged at customs, impounded for a month, and the company was hit with a five-figure fine for non-compliance. Even worse, their customer canceled the contract due to the delay. On the flip side, I've seen companies waste tens of thousands of dollars annually using expensive bolt seals on internal warehouse transfers where a simple plastic seal would have provided all the necessary control. A mismatched seal is a critical business error with a very real and painful price tag.

Conclusion

Stop the debate of plastic versus metal. Start thinking like a security architect. Deploy fortress-like metal seals for high-value, high-risk shipments, and use intelligent, information-providing plastic seals to manage your internal processes.

Build Your Smart Security System Today

At ProtegoSeal, we provide the tools for both the Fortress and Information philosophies. We can help you analyze your needs and design a multi-layered security system that is both effective and cost-efficient. Contact me to build a smarter sealing strategy.